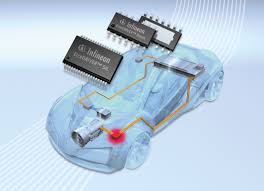

Semiconductor chips are a key enabler to the future advancements of automated cars and Infineon Technologies, an automotive leader for more than 40 years, is helping the automotive industry advance this exciting transition. Infineon builds complete chip solutions using its advanced processing, sensing and power management technologies for our future generation of reliable automated vehicles

Infineon semiconductors are used by automotive manufacturers in the vehicle body, powertrain, safety, and hybrid and electric vehicle applications. The company has more than 40 years of experience in automotive applications and standards. Many automated vehicles are including electrified powertrain solutions for their main mode of propulsion. In May 2016 Infineon released its latest power module family HybridPACK™ Double Sided Cooling (DSC) for hybrid and electric vehicle. In order for OEMs to meet CO2 regulations worldwide by 2020, they will need to add more electric or hybrid vehicles (HEV) to their fleets. The targets amount to only 95 gram CO2 per kilometer in Europe, 121 g/km in the US, 117 g/km in China and 105 g/km in Japan. “When electrifying existing car platforms, space constraints are a significant challenge. As the inverter has to be placed in the typically cramped engine department, it has to be as small as possible. Inverter size is mainly defined by the power modules employed. Consequently, these have to become smaller, while at the same time providing sufficient power to actuate the electric drivetrain. The size of a power module, on the other hand, is defined by the power consumption of the power chips used inside, and the ability to cool these chips to stay below a maximum junction temperature,” says the company.

Helping to overcome these challenges, Infineon’s new power modules have been reduced in size to 42 mm x 42.4 mm x 4.77 mm. They are designed for HEV applications such as main inverters and generators with a typical power range of 40 to 50 kW. They can be used in parallel configurations to support higher power requirements. The module can be directly attached to a cooler without external isolation, thus simplifying system integration.

Each integrated IGBT chip is equipped with an on-chip current sensor for overcurrent protection. In addition, an on-chip temperature sensor provides derating and fast shut-off in case of over-temperature.

Typically, there are up to three radar systems in vehicles equipped with driver assistance functions. In the future, with fully automated cars, up to 10 radar systems and 10 more sensor systems using camera or lidar technologies may potentially be utilized.

In a major step forward towards the fully automated car, semiconductor manufacturer Infineon Technologies AG and nanoelectronics research centre imec have entered into a partnership to develop a CMOS sensor chip. The partners are working on highly integrated CMOS-based 79 GHz sensor chips for automotive radar applications. Imec contributes its advanced expertise in high-frequency system, circuit and antenna design for radar applications thus complementing Infineon’s radar sensor chip knowledge.

“Infineon enables the radar-based safety cocoon of the partly and fully automated car,” said Ralf Bornefeld, Vice President and General Manager, Sense & Control, Infineon Technologies. “In the future, we will manufacture radar sensor chips as a single-chip solution in a classic CMOS process for applications like automated parking. Infineon will continue to set industry standards in radar technology and quality.”

“We are excited to work with Infineon as a valuable partner in our R&D program on advanced CMOS-based 77 GHz and 79 GHz radar technology,” said Wim Van Thillo, program director perceptive systems at imec. “Compared to the mainstream 24 GHz band, the 77 GHz and 79 GHz bands enable a finer range, Doppler and angular resolution. With these advantages, we aim to realize radar prototypes with integrated multiple-input, multiple-output (MIMO) antennas that not only detect large objects, but also pedestrians and bikers and thus contribute to a safer environment for all.”

Automotive Industries (AI) asked Shawn Slusser, Vice President, Automotive Segment, Infineon Technologies, what are some of the solutions the company has developed for autonomous vehicles.

Slusser: Some of the autonomous drive applications we support are electronic power steering; radar sensing; camera sensing; driver monitor sensing; automatic emergency braking; auto pilot/sensor fusion control units; electric vehicle inverters; on-board connectivity units with integrated cyber security.

Products designed for these applications include our 32b microcontroller family (Aurix™) with functional safety and security benefits; our DC/DC safety system power supplies designed to meet functional safety requirements; our 77 GHz radar chipset: our 3D image sensor (REAL3 tm) based on time of flight; security chips for automotive cyber security; and high-power IGBT modules and components.

AI: What are the safety challenges that need to be addressed?

Slusser: For autonomous cars to become a reality, four major challenges need to be addressed.

1) Implementation of functional safety systems into vehicles. This is already well underway in the industry.

2) Implementation of cyber security standards & solutions for the vehicles. Progress is being made in the industry. However, no minimum set of requirements has been defined for vehicles.

3) Redesign of the automotive power distribution architecture to ensure redundant power feeds and eliminate single fuses. This is necessary because autonomous drive electronics systems will always need to have a redundant power feed to maintain safe operation during a single point power failure.

4) Definition of government regulations and requirements for autonomous drive vehicles. This is being worked on by the US government currently.

AI: How do you see Infineon’s and imec’s highly integrated CMOS-based 79 GHz sensor chips for automotive radar applications changing the landscape?

Slusser: The CMOS based 79 GHz radar chips are enabling applications in the lower cost / lower range applications that have either been using 24 GHz SiGe technology today or even completely other technology like ultrasound. Examples of these applications are automated parking and blind spot detection.

CMOS comes into its own when high volume meets standardized components. Only then can the high NRE cost can be recovered. SiGe will remain the primary choice if lower volumes and higher flexibility in the system architecture and design counts. Application examples here are adaptive cruise control, highway assist and autonomous emergency breaking beyond urban conditions.

AI: When will they become available?

Slusser: Beyond 2020.

AI: How do you see your new power modules helping vehicles become ‘greener’?

Slusser: Infineon’s latest power module technology continues to reduce electrical losses and physical size. These improvements mean car makers can make more affordable HEV and BEV systems with extended range which helps accelerate the market acceptance for the next generation of green transportation.

AI: What are some of the challenges facing automotive OEMs when meeting new emission targets?

Slusser: One challenge is: What is the best OEM ROI for improving fuel economy (CO2 emissions)? There is no single solution for every OEM and we see them continuously evaluating to find the best approach for their own customers.

AI: How closely does Infineon work with automotive customers when developing new technologies?

Slusser: We work very closely with Tier 1 customers and OEMs for defining and developing new technologies. We have a dedicated team that works with OEMs to understand upcoming vehicle trends and help to translate the system needs into valuable technology and product innovations. Since the semiconductor technology design cycle is relatively long, we have to be working so far ahead to insure products will be available when an OEM releases specs to the supply chain.

Cloud-based TMS simplifies management of global logistics chains

Cloud-based TMS simplifies management of global logistics chains Connectivity and audio quality driving customer choices

Connectivity and audio quality driving customer choices The brains behind the world's most intelligent executive saloon

The brains behind the world's most intelligent executive saloon Access to data opens  up new revenue stream  for OEMs

Access to data opens  up new revenue stream  for OEMs ChargePoint Raises $82 Million to Pave the Way for e-Mobility in Europe

ChargePoint Raises $82 Million to Pave the Way for e-Mobility in Europe High-end 3D visualizations add a new dimension to car marketing

High-end 3D visualizations add a new dimension to car marketing