Donaldson – Introduction to Combustible Dust

The airborne dust created by many manufacturing processes is no mere housekeeping problem. Once those

Donaldson – Combustible Dust Management

Mitigate Combustible Dust Fire and Explosion Risks A well-designed, maintained, and operated dust collection

Proactive Approaches to Avoiding and Dealing with Work-Related Litigation

Having the right policies and procedures in place for your business can help you avoid

ROHM’s New Linear Op Amp Features Industry-Low 160nA Current Consumption

ROHM Semiconductor announced a new linear operational amplifier (op amp), the LMR1901YG-M, featuring the lowest

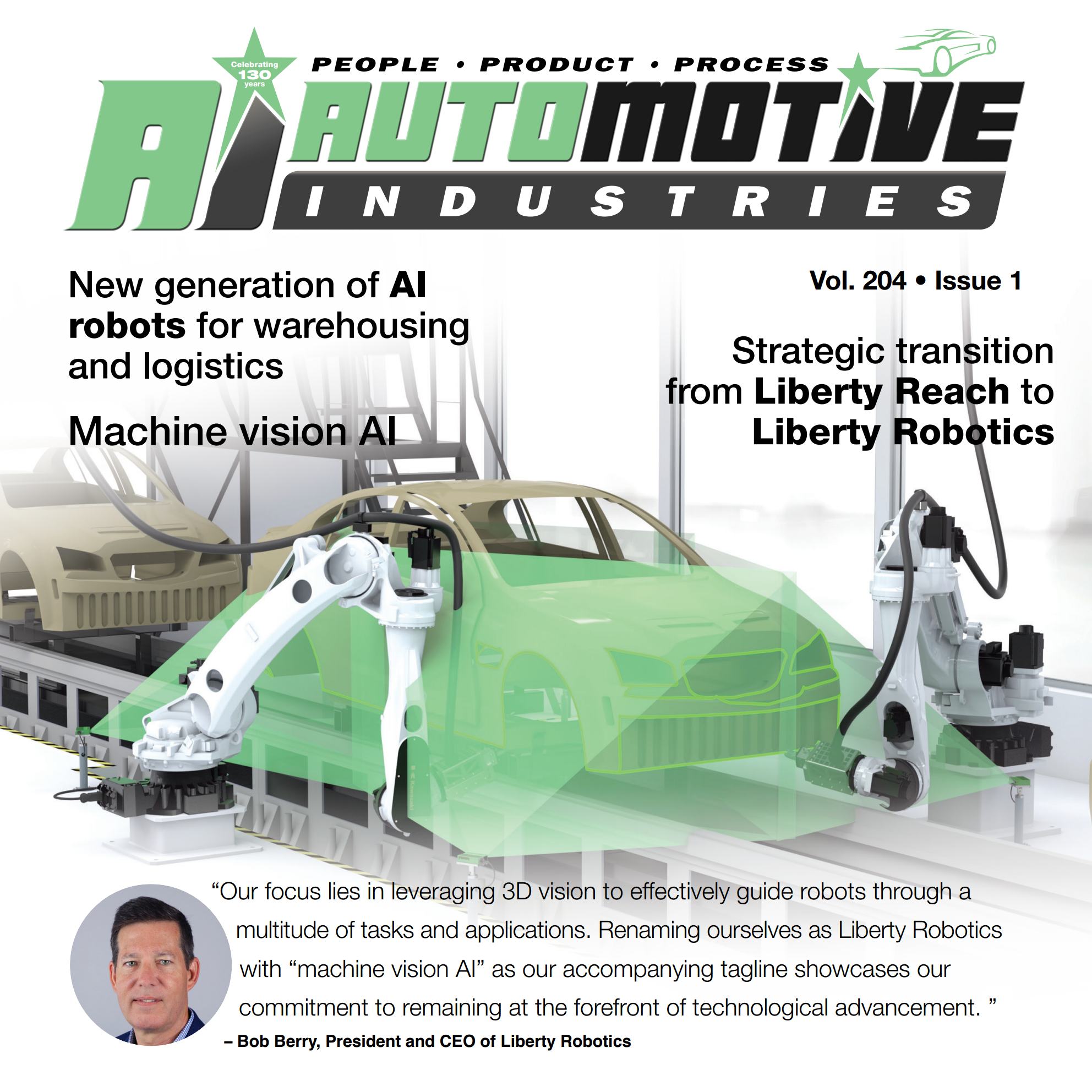

Liberty Robotics 3D guidance systems a game changer for warehouse efficiency

A new generation of autonomous robots is using 3D volumetric vision guidance systems to meet

DMC integration sparks efficiency and precision in ams OSRAM’s LED solutions

Automotive Industries interview with Anita Wenzl, Senior Product Marketing Manager at ams OSRAM Group The

Japanese vs American Cars – An Automotive Battle of Titans

The global automotive scene serves as an arena, featuring two of its most illustrious players,

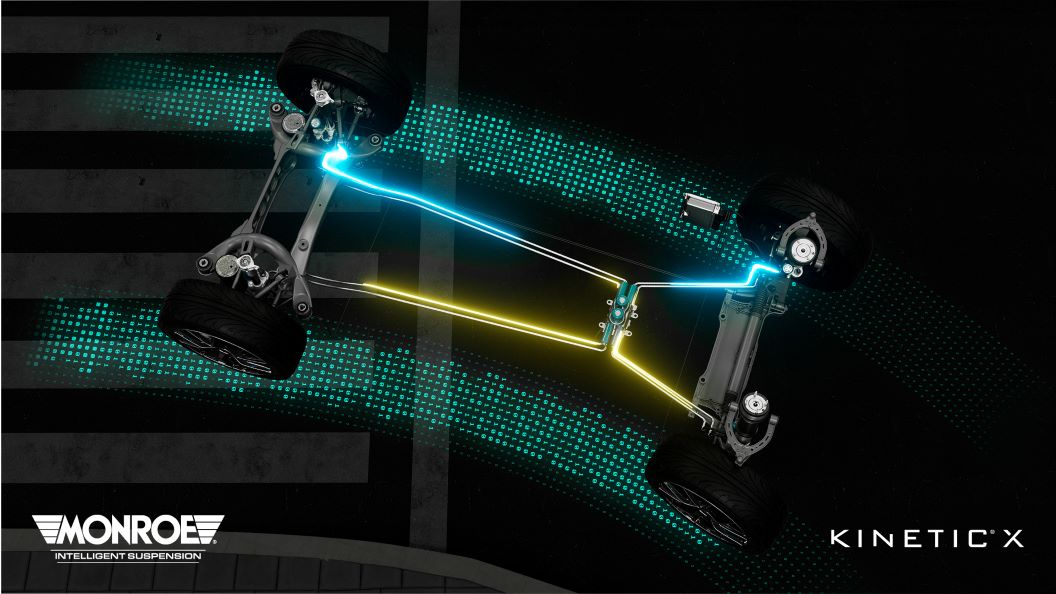

Monroe Intelligent Suspension KINETIC® X: Revolutionizing vehicle dynamics

Monroe® has commenced the serial production of Monroe Intelligent Suspension KINETIC® X system. Introduced in

VinCSS & C2A Security’s strategic partnership fortifying compliance and vehicle security in the connected car era

Automotive Industries interview with Tin T. Nguyen, Director, Automotive Cybersecurity Services, VinCSS In the dynamic

Ongoing Luka Koper port investment drives position as major automotive hub

Operators of Slovenia’s strategically positioned Luka Koper port continue investing in the facility, which has

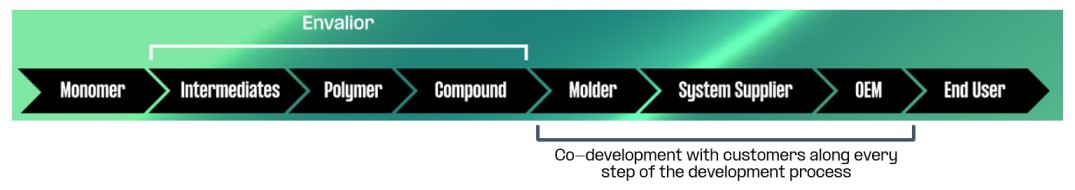

Envalior – a “new” Engineering Materials company with over 100 years of expertise

Formally established in April 2023, Envalior is the combination of complementary industry leaders in the

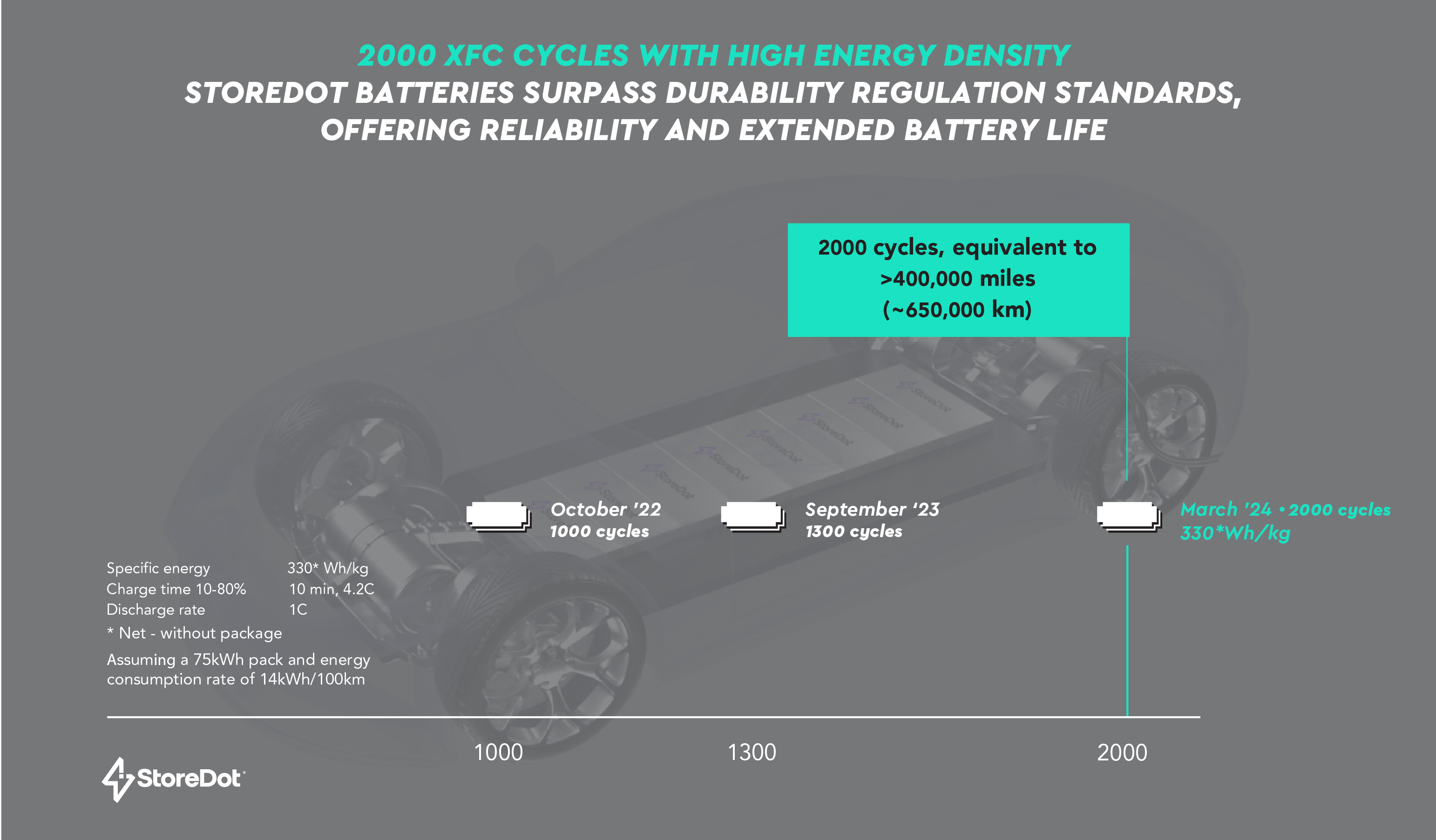

StoreDot hits Commercialization Milestone with 2,000 Extreme Fast Charging (xfc) Cycles

StoreDot, a leading developer in electric vehicle (EV) battery technology, has reached a significant milestone

Aspinity Establishes Technical Advisory Board of Seasoned Semiconductor Industry Veterans

Aspinity, the leader in near-zero power AI solutions, today announced the formation of its technical

Comparing Cordless vs. Corded Tire Inflators Pros and Cons for Garage Owners

In today’s fast-paced automotive world, the tools we use in our garages play a pivotal

Exploring innovations at the 45th Bangkok International Motor Show 2024

The automotive industry is constantly evolving, fueled by technological advancements, sustainability goals, and shifting consumer

Gaël Escribe unveils NEXUS’s Automotive Aftermarket triumphs in exclusive interview with Automotive Industries

Automotive Industries interview with Gaël Escribe, CEO, NEXUS Automotive International In the ever-evolving landscape of

Navigating Electrification, Software-Defined Vehicles, and Collaborative Innovation in a World of ‘Smartphones on Wheels’

Automotive Industries interview with Andreas Heim, VP of Engineering, Automotive, Flex and Nicole Stevenson, VP

How To Improve Your Truck Driver’s Behaviour

Truck driver’s behavior have a significant impact on road safety, company reputation, and overall business

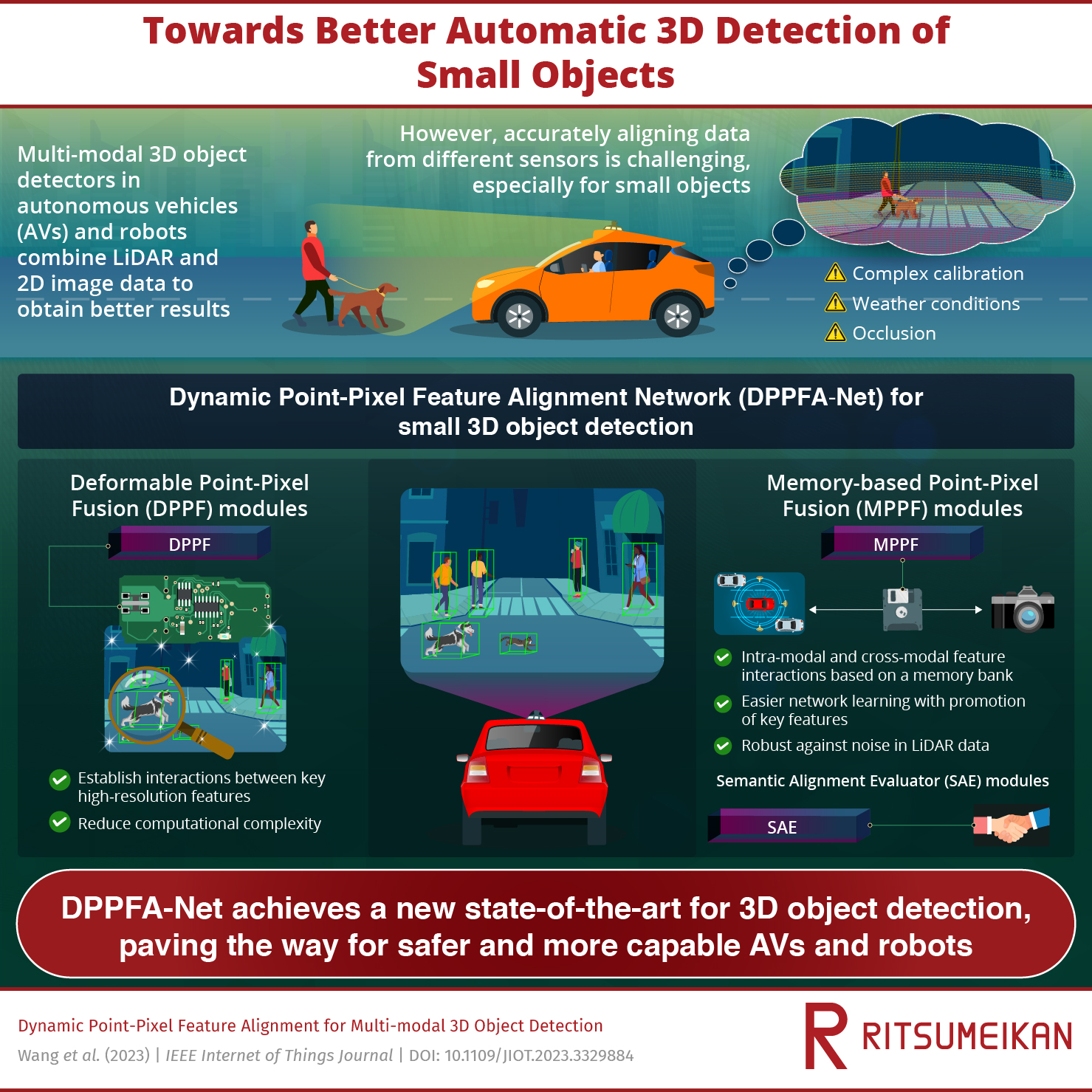

Towards More Accurate 3D Object Detection for Robots and Self-Driving Cars

Robots and autonomous vehicles can use 3D point clouds from LiDAR sensors and camera images

Pre-Switch CEO, Bruce Renouard Joins Executive Board of Leading University School of Engineering

Pre-SwitchR, Inc., the company that developed the world’s first AI-based forced-resonant, soft-switching technology enabling ultra-efficient

StoreDot’s Advanced Technology Campus is now Operational in Irvine, California

StoreDot, the pioneer and world leader in extreme fast charging (XFC) battery technology for electric

Launch of Greenpower Park – the UK Centre of Electrification and Clean Energy with West Midlands Gigafactory

Plans to place Britain at the epicentre of the green industrial revolution have taken a

Somerset home to new gigafactory, confirms Agratas

Somerset will be home to a new multi-billion-pound electric vehicle battery manufacturing facility in the