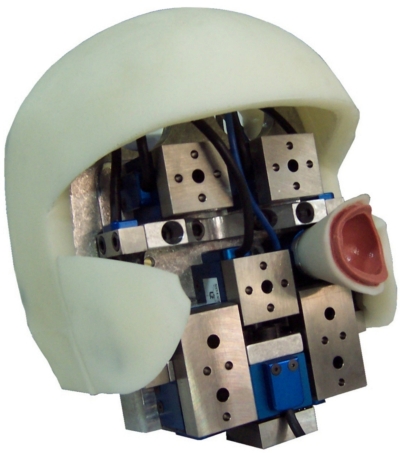

Robert A. Denton Inc’s Facial and Ocular CountermeasUre for Safety Headform (FOCUS) made an impressive debut at the SAE World Congress held in Detroit this April. FOCUS is a mechanical head that provides a test platform for eye and facial injury studies. FOCUS has been developed as a modular system with the ability to add instrumentation for a variety of test scenarios. Denton developed FOCUS in collaboration with Virginia Tech’s Wake Forest Center for Injury Biomechanics and the United States Army Research Laboratory. FOCUS will be used by the US Army to test and evaluate various protective devices and other equipment under impact events, says Denton.

FOCUS can also be used to study facial effects from airbag impacts, motorcycle-related injuries as well as sports injuries. The headform sensors allow engineers to study five different facial bones: frontal, maxilla, zygoma, mandible and nasal.

Denton is a global leader in the manufacture of anthropomorphic test devices (ATDs – commonly known as crash test dummies), dummy laboratory certification equipment and load cells. At the SAE World Congress in April, FOCUS was not the only Denton technology that evinced interest. The company’s RibEyeâ„¢ Thorax Displacement Technology was also of great interest.

“RibEye™ is crucial to being able to track and measure rib deflection in two or three dimensions. Before RibEye™, the available devices could only measure rib deflection in one dimension –with questionable accuracy and reliability. With RibEye™, safety engineers are able to track up to twelve points in three-dimensional space. This is very important to understanding what happens to our ribcage in an automobile accident, in particular side impacts, and the development of an injury criteria for safety testing,†said David Stein, President and Chief Executive Officer of the Denton Companies, in an earlier AI interview.

Robert A. Denton, Inc. established the Ohio-based Denton ATD, Inc., in July 2000 with the purchase of Applied Safety Technologies Corporation. Denton ATD manufactures a full range of regulated and non-regulated crash test dummies and dummy laboratory certification equipment for the automotive, aerospace and transportation related industries. Robert A. Denton, Inc. has long been recognized as the world leader in the development and manufacture of load cells designed specifically for use in crash test dummies and safety related testing.

Some of the new products the company has launched over the past year include (apart from RibEyeâ„¢ and FOCUS) NxT, developed by Denton and Kayser-Threde (manufacture of the MicroDAUâ„¢ data acquisition system). NxTâ„¢ is a unique in-dummy and in-sensor data acquisition system that allows a higher level of data integrity in crash test dummies and eliminates external wire bundles.

Other technologies Denton is working on include advanced sensor technology for measuring shoulder forces from seat belt loading conditions and a lightweight seat belt load cell.

The automotive industry is an important one for Denton, which targets a lot of its technology to this sector. “This is an exciting time to be involved in safety testing. More than ever before the consumer is aware of, and making buying decisions based on safety ratings of an automobile. This has been a significant driver in advancing safety research. There is also the continued expansion of the auto-manufacturing base as new manufacturers come on line (China for example) and existing manufacturers expand into new markets. In addition, we are realizing there are many other places we humans are put into harms way where research using a human surrogate – a crash test dummy – can save lives. In addition to child seats, which have gotten so much attention in recent years, recreational vehicles, motorcycles and the aircraft industries are all are looking at ways to improve the safe use of their products. We are also see increased use of dummies in the testing of military vehicles, in particular protecting occupants from land mines,†said Stein to AI.

Automotive Industries caught up with David C. Stein, president and CEO of the Denton Companies, to ask about the company’s latest technologies.

AI: What was the industry’s reaction to FOCUS when it debuted this April?

It was very positive. There is a lot of interest not only from automotive safety but sport safety as well. In addition to being able to map facial interaction with an automotive interior, FOCUS could also be very useful in evaluating the effectiveness of helmets, goggles, and other types of face guards and shields used in a variety of sports. Some military visitors even suggested we compliment the current sensor package with pressure transducers to measure blast pressure.

AI: Is FOCUS commercially launched or is it still under development?

We have delivered the first units to Virginia Tech University. The initial tests went very well. We are quoting the units now with anticipation of being able to begin shipments by the fourth quarter of this year.

AI: How do you think FOCUS will change automotive safety testing?

Data collected from FOCUS could result in a change of safety technologies (air bag designs) versus a change in safety testing protocols.

AI: Please tell us a little about Denton’s focus on creating a new standard in ATDs?

For many years the ATD was tasked with helping the engineer detect and quantify gross injuries. That is, those injuries that could cause a fatality. Today, most people are surviving automobile accidents but are sustaining injuries that affect the quality of life. ATD’s are now being tasked to measure in ever smaller increments, the degree of injury and they’re not designed for that. The next generation ATD will need to be more biofidelic, more sensitive to a broader range of inputs (lower impacts as well as high), and will most likely include a broader array of instrumentation.

AI: What are some of the new technologies Denton plans to launch over the next year?

We are introducing new configurations of the RibEyeâ„¢ technology. We have added another axis to the measurement system so we can now measure displacement in three dimensions. The first application of this is in the SID IIs side impact ATD. We are also doing a lot of exciting work in the area of materials and modeling.

More Stories

Towing Services Explained: 6 Key Facts You Need to Know

Environmental Factors That Influence Ceramic Coating Choices

Professional vs. DIY Tinting: What You Should Know