Everyone talks about the ‘Smart Factory’ as the next big thing for manufacturing, but what will it mean for your factory and how can you make it a reality?

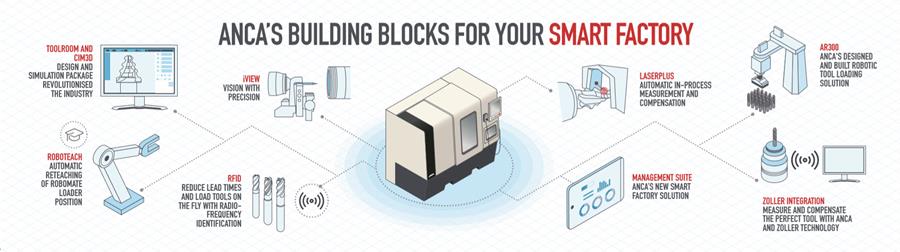

Tool manufacturers are looking for practical solutions to embrace automation and gain functionality that are adaptable to their own needs; size, scale, and market segment. ANCA is working to deliver a range of machine, software and process solutions that can deliver measurable gains in productivity, quality and ultimately, a factory’s bottom line profit. Automation is no longer only a trend; it is a destination.

Visit ANCA at Hall 7, Stand 7045 <https://storymakerpublicrelationsgmbh.cmail19.com/t/i-l-xykuutt-jjkdkyyuld-r/> for a live demonstration of interconnected grinding technology solutions that will eliminate wasteful manual handling, reduce machine downtime in between batches and take away the need to have operators constantly monitoring and adjusting production machines.

Delivering an end-to-end production system for complete tool production

ANCA’s industry-firsts and technological innovations have driven customer-focused solutions towards factories of the future for nearly 50 years. Extending on this and connecting separate steps of the tool grinding process with the latest automation and information management systems – tool production can be transformed. The key to smart factory solutions is automation; reducing manual handling to enable any businesses’ most valuable resource – people – for highly skilled, value creation.

As machines are increasingly connected to one another, managing data and data systems is another essential ingredient in a functioning smart factory. ANCA’s critical data management solutions cater for an integrated network of machines, to bank the benefits of automation. ANCA’s software solutions consider measurement data that must be correctly applied across machines for process control and visible for quality control, ERP data to make sure the right job is done on the right machine at the right time, or monitoring process and machine performance data using ANCA’s UMATI compatible RedaX system.

Lights out manufacturing is a reality in CNC grinding. Swiss tool maker Fraisa’s investment in automation reduced production costs by 50% with a customised solution from ANCA. Amelinda Ilardi, ANCA Engineering Project Manager explains the solution:

ANCA launches new mixed batch automation for unattended regrinding with ANCA’s FX7

Tool service providers are embracing automated solutions for unattended regrinding. At Grindtec, ANCA will show a new collet changing solution on the FX7; increasing versatility and productivity for mixed batch resharpening on its most economical platform.

Depending on their batch sizes resharpening services want to be able to run their machine unattended with a small mixed batch of tools over a lunch break or for a couple of hours after regular working hours. Market feedback shows that many medium-sized companies are looking for increased tool loading capacity and added flexibility. The new collet changing solution from ANCA meets the requirements of medium-sized tool service providers who are looking for solutions to run their machines for several hours unattended or even lights out.

ANCA is expanding its offering for automated tool loading of mixed batches, ranging from small mixed batch resharpening with the ANCA AR300 and collet loading to large-scale industrial regrinding solutions with RFID workflow, allowing chaotic loading on the MX and TX product platforms.

The new FX7 collet changing solution will not only close the gap, adding extended tool loading capacity opposed to AR300 collet loading, but will also be the most affordable solution for unattended mixed batch sharpening on the entry level FX product platform combined with new software enhancements.

Manufacture complex tool geometries with perfect balance with the latest generation ToolRoom RN34 software

ToolRoom RN34 is a specially designed software package for the aerospace, die mould, general machining and power generation industries, offering improved and intuitive creation of complex endmill geometries.

“Direct communication between design and simulation software packages has simplified tool balancing and made it a breeze,” says Thomson Mathew, Software Product Manager.

Douglas Franke, Fraisa Production Manager said: “With ANCA’s balancing software we have a tool balanced generally within five minutes. Some of our more complex tooling can take a little longer – up to 20 minutes. This drastically decreased our time in setup on the machine which could take several hours. Our biggest success story has been an aerospace customer who is running our 1” aluminium roughing tool at 25k rpm.”

ToolRoom’s features also include a ballnose chisel grinding feature, designer cutting edge, pocket grinding applications, lollipop cutters, protection for grinding files and other enhancements in profile software and other ToolTypes.

ANCA’s GCX Linear offers a comprehensive gear cutting package for the growing skiving market

The popularity of skiving applications continues to rise: driven mainly by the need for high quality internal gears for electromobility. Responding to the market, ANCA’s GCX Linear builds on the best aspects of ANCA’s proven technology to offer a purpose-built solution for manufacturing and sharpening skiving cutters. As a five axis CNC grinder powered by LinX linear motor technology on X, Y and Z axes, the GCX Linear also comes with features specially designed for skiving cutters and shaper cutters.

* Motor temperature control (patent pending), minimises machine warmup time, and delivers optimal thermal stability during grinding

* Full process virtualisation on design station before grinding: Design, Optimise, 3D Simulation, MRR Estimation and more

* In-process dressing with acoustic emission monitoring system (AEMS) and supervised machine learning algorithm

* Dedicated gear cutting tool software package

* Five axis CNC grinder, with LinX linear motor technology on X, Y and Z axes

* 37kW (49HP) peak power direct drive spindle with BigPlus arbor

* High accuracy headstock offers greatly improved index positional accuracy

About ANCA

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, India, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

More Stories

Sonatus – The industry is shifting gears to software

Cybord warns of dangers of the stability illusion

HERE building trust in ADAS systems