Technical experts carrying out simulation and testing work,

It is no longer news that the automotive industry is in a state of disruption. The move to electric vehicles has opened up the market to new players which are not encumbered with a ‘this is the way we do things in the auto industry” mindset.

Existing OEMs and Tier suppliers have to rethink their business models and approach to research and development in order to stay relevant and competitive.

Automotive Industries (AI) asked Roger Calixto de Araujo – Battery Systems, Adhesives Automotive Components at Henkel – how the company is adapting.

De Araujo: It is a huge challenge to change from the traditional way the automotive industry has handled the development of new products. In order to stay competitive, you need to be able to develop really fast, to shorten your timelines and to be cost-effective.

Added to that you have the evolution of customer expectations coupled with new ownership models that focus on e-mobility. This evolution leads to greater customization expectations by each customer. In order to meet the challenges, we have to use digital innovation to be both competitive and sustainable.

AI: How is Henkel handling digital transformation?

De Araujo: Henkel is the largest additive manufacturer in the world and has the capability to adapt and take advantage of the opportunities. An example is the establishment of our Innovation Centre at our headquarters in Dusseldorf. This has changed the way we develop our products. Engineers, salespeople, customers and business development specialists come together and share the same environment. This lowers all the fences that traditionally separate people and departments.

Another example is an integrated research and development data collection tool we call Albert. It collects data from every experiment that we do in all our different labs and harmonizes it so that we can identify opportunities by analyzing and interpreting the information.

In the battery and e-mobility fields Henkel saw the need to have dedicated experts. The dedicated battery expert team is reviewing all the different aspects of battery development and adapting the products and the expertise Henkel has accumulated into this new field. We are looking forward to bringing modelling simulation as much as possible into battery development to really speed up the integration of designs and also to be more efficient, cost effective and faster.

Ai: What areas is the battery team targeting?

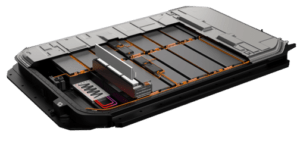

De Araujo: The four areas are battery safety, battery cell technologies, battery sustainability, and design integration. On the safety aspect, Henkel materials can definitely play a huge role in managing fire and thermal propagation prevention. As an examples we are carrying out the development of fire protective coatings for battery lids, and thermal isolation solutions across battery cells, like potting materials and Fire Protection Pads.

For the battery cell technology, we are focused on the development of conductive coatings to improve active material adhesion to the current collectors and enhance the electrical conductivity of those interfaces, also the development of dielectric coatings for battery cell housings as an enabler for better mechanical and thermal performance. Our experts are keeping, as well, a close look into how we can play a role into disruptive technologies trends like solid state batteries and fuel cells

On Sustainability area, product-wise, one of our focus topics lies in enabling a circular economy for batteries with our solutions. Having options to repair, repurpose or to reuse batteries is crucial to lower the dependency on critical raw materials by extending the product lifetime. In that sense, facilitating the possibility to disassemble batteries in an efficient way is key. Henkel has a huge role to play here by developing adhesive solutions, that allow for debonding on demand. We are working towards allowing the repair, repurpose, and reuse of battery components – and ultimately provide solutions for an efficient way of recycling the valuable materials from batteries at end of life..

Looking at design integration, battery designs are gradually assuming other functions on a vehicle level rather than being simply a power source, the

trends on integrating the battery pack to the vehicle structure is a good example. When you start bringing those multifunctionalities together, opportunities for more efficient materials to the allow for the best performance in the battery system attributes.

AI: What are the other main battery trends?

De Araujo: Mainly those trends are related towards increasing energy density within batteries, and prevention of uncontrolled thermal events. You can tackle those problems from a variety of ways, from cell chemistry and size, passing through the battery design, and the control software strategy. We see now some major changes in the approach to battery design, with OEMs approaching it differently. But whatever technology is being proposed, like immersion cooling, phase changing materials, new chemistries, etc. You must fine-tune what you actually want to deliver to your final customer. For instance, we have this relationship between vehicle range and charging performance. Increasing the size of the battery packs means more weight, which may not be the most efficient solution for increasing vehicle range. Another solution could be to develop batteries that

can recharge fast. In essence, you will need smaller and lighter batteries that wouldn´t require long charging times when big range is needed – what might be acceptable to costumers while on a road trip. Finding the right balance for the final customer has a lot to do with the type of use intended for the vehicle, and what materials are inside the battery. Henkel has the right materials to ensure that our costumer can hit this sweet spot.

AI: What role does modelling and simulation play?

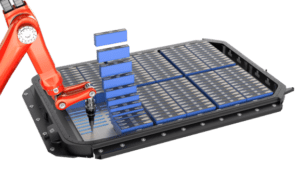

De Araujo: In order to be more dynamic and to have faster turnaround times we need to go digital. Our team of modeling experts is bringing together deep development on four major workstreams through the modelling and simulation of batteries.

The first is application modelling – how we dispense and apply high viscosity liquid materials like adhesives. This modelling helps us to determine, for example, how much force is needed to compress the material to provide the desired bond line thickness.

It reduces time to market because, instead of doing lab trials and so on, I can model the material behavior, how the flow and rheological characteristics of the material are throughout dispensing and assembly processes, and also allows us to optimize the formulation of materials.

The next focus is on the thermal modelling of batteries. We want to really master the thermal pathways within battery systems. We know that, in some cases, we need to extract as much heat as possible. But, for safety reasons in some regions, we also have to ensure that the insulation is as good as possible.

This may seem contradictory, but we have to understand where we want the heat to go and how we want it to flow. We also need to model the thermal characteristics and battery behavior in extreme scenarios such as thermal runaway. Of course, this has a lot to do with specific customer designs. But, in essence, we want to fully understand the thermal behavior in order to work with our customers to provide solutions for the most efficient design.

The same is true for mechanical and structural modelling. We need to understand the stresses on the battery packs and cells as they become structural elements of a vehicle. How are the loads transferred? What role are the adhesives playing when it comes to safety if there is a crash? We need to understand how those different elements interact. Modelling is crucial in order to do that.

Modelling also speeds up the formulation of materials. We can predict in a very detailed way how a material will behave in terms of rheology, thermal conductivity, stiffness, curing times and so on before we have a physical product.

AI: What’s next for Henkel?

It is to continue to be the leading provider of adhesive technology. We want to be seen as the experts when it comes to eMobility material solutions. In that sense there are a lot of changes on the horizon. Henkel is prepared to grab all those opportunities in order to be recognized as the best solution provider for e-mobility.

More Stories

DuPont materials science advances next generation of EV batteries at The Battery Show

How a Truck Driver Can Avoid Mistakes That Lead to Truck Accidents

Car Crash Types Explained: From Rear-End to Head-On Collisions