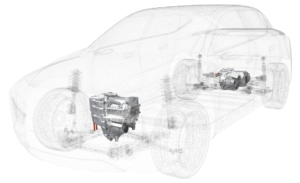

Magna used a holistic design approach for the electric vehicle drivetrain system.

Mobility company Magna used CES 2024 to introduce its next generation 800V eDrive solution that, according to the company, sets new standards in efficiency, power-to-weight ratio, and torque density.

The new eDrive is a drop-in solution that incorporates several advanced technologies which offers enhanced fitment flexibility due to its lightweight (75 kg) design and 20% reduction in height from Magna’s prior generation eDrive.

The system achieves up to 93% efficiency in real-world driving (including WLTC and highway), which significantly improves efficiency across a wide range of vehicle speeds, making it more versatile.

“We are steadfast in our commitment to creating exceptional driving experiences while supporting a sustainable future,” said Diba Ilunga, President of Powertrain at Magna.

“Our next generation eDrive is a true embodiment of this pledge, showcasing unparalleled sustainability in both its product design and production methodology.

“Through seamless integration of our systems, we have successfully reduced our reliance on aluminum and heavy rare earth materials, resulting in a significant reduction of CO₂ emissions during production by approximately 20% compared to previous generation eDrives.”

Automotive Industries (AI) asked Daniel Lindvai-Soos, Director Product Management, eDrives at Magna Powertrain, what the design philosophy was behind the new eDrive.

Lindvai-Soos: Basically, we set about by taking a holistic approach to the drivetrain system. Instead of concentrating individually on the gearbox, motor and rotor, we focused on the connecting element between all these three.

AI: Is it a true drop-in solution?

Lindvai-Soos: Absolutely. We catered for the next generation of vehicle architecture. For this we added a feature that allows us to rotate the product around the drive axis. This means can fit the unit to both or either the front and rear axles while freeing up more space in the trunk and the interior of the vehicle.

AI: Can Magna’s eDrive be applied as a primary or complementary secondary drive solution?

Lindvai-Soos: Magna’s 800V eDrive is based on a KPI driven generation approach and can be applied as a highly efficient primary or complementary drive with optional eDecoupling to battery electric vehicles from the C, D and E segments. It delivers a peak power of 250 kW and a peak axle torque of 5,000 Nm.

AI: How efficient is the eDrive?

Lindvai-Soos:

In real-world WLTC (worldwide harmonized light vehicles test cycle) and highway driving the system has been proven to improve performance by 93% across a wide range of vehicle speeds, reflecting gains in both energy efficiency and versatility.

Let us take the example of a premium vehicle capable of doing 180 kph on a German highway.

This is where you really need a higher range of efficiency to that measured by the WLTC.

The eMotor delivers 8 kW per kilogram, which is also pretty outstanding compared to existing electric motors.

AI: What is your approach towards sustainability with new product design and production methodology?

Lindvai-Soos: It is a continuous approach to sustainability in product design.

Our designers strive to minimize the use of rare minerals and other materials.

Less than 0.5% of the weight of the eDrive magnets is made up of heavy rare earth materials, which are mainly Dysprosium and Terbium.

The weight is equivalent to two cubes of sugar per electric motor.

This reduces our CO2 emissions in the value chain one the one hand.

On the other hand, we are using 99% recycled aluminum, and we use much less material in our housings than previous generations of the eDrive system and competitor products.

This is how we have increased the power density over time through our focus on minimizing the amount of material used per unit.

We also focus on recycling. Aluminum is just one of the recycled materials we are working on, in addition to minimizing the use of critical materials like heavy rare earths.

Looking to the future, there are design elements, such as reducing maintenance and replacement of the rotor through the mix of materials we use.

AI: Which vehicle segments are you targeting with the new solution?

Lindvai-Soos: It is a scalable solution. We showcased the 250 kW. It can be downscaled to 150 kW, and upscaled to over 350 kW.

Basically, it is the full range from C segment main street types up to the premium sports segment.

AI: What are the biggest challenges for you at the moment?

Lindvai-Soos: The biggest challenges the whole industry is facing are inflation, energy prices and supply chain limitations.

There are regional challenges in terms of local design requirements and quality standards.

We take these aspects into consideration in our design of our product, and also the supply chain of the future.

AI: What is next for Magna powertrain?

Lindvai-Soos: We want to strengthen our roadmap further to ensure we make a product which contributes to a greener future. We will make it greener by reducing the use of rare materials even further.

And we want to make the eDrive even more energy efficient, to meet the requirements of different manufacturers.

More Stories

Towing Services Explained: 6 Key Facts You Need to Know

Environmental Factors That Influence Ceramic Coating Choices

Professional vs. DIY Tinting: What You Should Know