“New environmental regulations force a change from the currently used glues to new solvent-free ones†– Ernesto Angelo Cullino, president of NKE

Environmental regulations are forcing manufacturers of bonding liquids to reformulate the glues and devise new ways of applying them, says Ernesto Angelo Cullino, president of NKE.

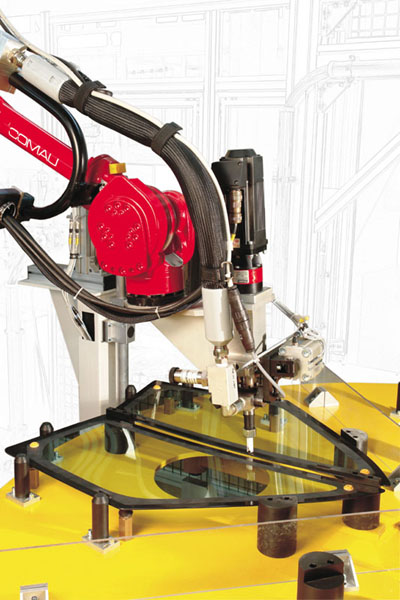

Turin, Italy-based NKE manufactures adhesive and sealing application plants, fluid dispensing plants, test station and leak test systems, as well as electronic components for the automotive, aviation and other industries. “New environmental regulations force a change from the currently used glues to new solvent-free ones,†he says.

NKE invests 5% of its annual turnover in research in the chemical, electronic and mechanical fields. Its activities are mainly geared to the body shop and to the final assembly operations in automotive industries – any type of metal sheet and glass gluing. Automotive Industries spoke to Ernesto Angelo Cullino, president of NKE and Piercarlo Collini, technical manager at NKE Automation.

AI: Who are some of your automotive clients?

NKE: Our main Customers are Fiat Auto, Maserati, Ferrari, IVECO, SAAB and Avtovaz. We deliver and install assembly, gluing and filling stations and/or lines wherever in the world they have manufacturing facilities.

AI: Are you focused solely on the European market?

NKE: Currently we are focused on the European market where we set-up in each involved country local service facilities with properly educated personnel. We are interested in expanding our market into North America but we have first – due to the distance – to establish good relations with a local dealer or representative.

AI: What are some of the recent technological breakthroughs made in the automotive adhesives and sealants markets and how was NKE Automation incorporated these changes?

NKE: The gluing technology has been conservative in the last years. What has changed is the process itself with special focus on the cycle time. NKE put a lot of development efforts in the handling of glass in order to get better accuracy in the glass’ indexing and manipulating. In the same time we designed a new gluing head with an integrated delivery valve and a very short pass-through of adhesive. That means high efficiency and very low maintenance. The new single column barrel pump also offers space saving.

Precision Standards require continuous improvements to guarantee reliability and repetitivety of the different process’ phases. All these (and others) needs are behind NKE’s development activity.

AI: What are some of the trends in the automotive market that you feel will change the nature of your industry?

NKE: Globalization and close cooperation between various Automotive Industries require to keep very close relations with different Manufacturers’ Departments in order to harmonize all suggestions and requests: NKE’s staff is properly trained to follow-up such opportunity.

AI: What are your plans to increase your reach – do you plan to open subsidiaries in other countries?

NKE: We are focused to set-up a new structure in Far East. We consider India as the best Country from which to establish a commercial and production subsidiary that could serve the whole eastern area. Of course the development and main designing operations will continue to be managed from the head quarter in Alpignano.

Full video with one twisted pair

Full video with one twisted pair Flexray Consortium goes for speed

Flexray Consortium goes for speed Integrating logistics the DHL way

Integrating logistics the DHL way Making bodies to order

Making bodies to order Breathe clean air

Breathe clean air Prototyping

Prototyping