Henkel launches new fire protection solutions for safer EV batteries

As the pace of EV adoption and innovation accelerates, OEMs and EV battery

manufacturers are striving to develop more efficient ways to build batteries

at scale. At the same time, fire protection remains critical to ensure

vehicle batteries provide the best possible safety in the case of accidents

and fires. This is especially important as regulatory demands become more

rigorous. Hence, EV battery safety technologies that delay the spread of

fire have never been more vital.

To take on this challenge Henkel, a leading partner to the automotive

industry, has launched two new protective coating products designed to

shield the battery housings against heat and fire in the case of a thermal

runaway event – Loctite EA 9400 and Loctite FPC 5060. When applied to

battery packs, the coatings help to inhibit and delay the spread of fires to

protect the passengers as they evacuate the vehicle. Meanwhile, their

efficient and cost-effective application processes ensure that manufacturers

can continue to optimise battery production without compromising on safety.

“Battery safety is an increasingly important topic for OEMs and battery

manufacturers alike,” explains Stephan Hoefer, Market Strategy Head for

E-Mobility at Henkel. “Thermal runaway events are possible in any

lithium-ion battery, but the key is to minimise the risks and consequences.

At Henkel, we are seeking to minimise the impact of such events through

effective and practical solutions that can delay the spread of fire. This is

vital to ensure that passengers have sufficient time to evacuate the

vehicle.”

Whether due to mechanical, thermal, or electrical incidents – thermal

runaway events can occur when a battery cell enters into a heating state and

ignites a fire that spreads to neighbouring cells. Battery safety solutions

help to reduce or slow such events, thereby increasing time for vehicle

evacuation. This time window is increasingly subject to regulation: China

has already enacted regulations that specify a required time window and

other markets are expected to follow suit in due course as regulatory

frameworks for EV safety evolve.

“OEMs and battery manufacturers are challenged to find efficient solutions

that support large-scale automated manufacturing and position them well

against legal regulations. At Henkel we aim to anticipate our customers’

current and emerging challenges and hence developed purpose-built and tested

products specifically to help them meet this demand for fire protection in

EV batteries,” commented Uwe Franken, Global Technology and Product

Development Leader for E-Mobility at Henkel. “The launch of two new Loctite

coating products for fire protection demonstrate that battery safety is a

key focus area for Henkel.”

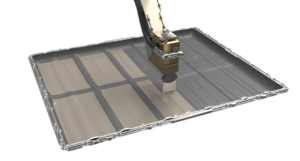

Designed for automated mass production, Loctite EA 9400 and Loctite FPC 5060

can be applied either by “spray” or “flat stream” and both are compatible

with common automated dispensing systems. In line with Henkel’s commitment

to sustainability, Loctite 9400 and Loctite FPC 5060 both cure at room

temperature, thereby helping to reduce energy consumption and emissions.

Loctite EA 9400

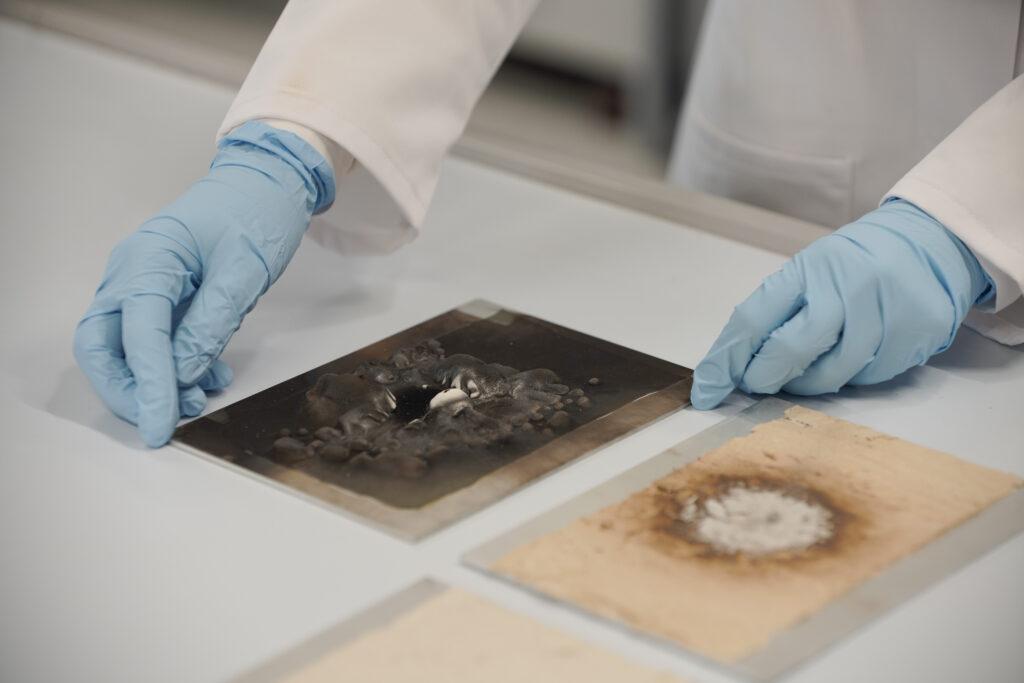

Loctite EA 9400 is a two-component, active flame-retardant, epoxy-based fire

protective coating designed for the battery pack housing. With minimising

weight of EVs and batteries a high priority, the product has been designed

to be applied in a thin layer that doesn’t add much weight to the battery.

Thanks to its foaming characteristics and tough formulation for outstanding

environmental resistance, Loctite EA 9400 can be applied on both the inside

and outside of the battery pack housing to provide excellent versatility. As

well as providing light-weight thermal protection, it also prevents battery

box corrosion.

Loctite FPC 5060

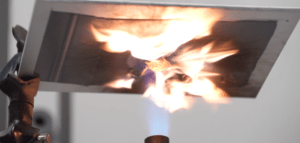

Also created for the battery pack housing, Loctite FPC 5060 is a

one-component, water-based, inorganic material that does not form any smoke

or fumes when exposed to flame. Its unique, inorganic formulation does not

include any hazardous chemicals and produces no smoke, no fumes, and no

carbon during a fire – thereby further protecting passengers.

“Electrification of transportation is a huge opportunity that also presents

numerous overlapping challenges for OEMs such as efficiently scaling up

production while ensuring the highest safety standards. This is where

innovative materials and processes will be mission-critical,” explained

Marvin Romberg, E-Mobility Business Development Manager EIMEA at Henkel. “As

a long-time trusted partner to the automotive industry, Henkel is helping

our customers stay ahead of the curve with state-of-the-art products built

on pioneering research. We are also providing our customers with

comprehensive support for process implementation and working in

collaboration with dispensing equipment suppliers to deliver a coherent,

joined up-approach across the entire value chain.”

More Stories

Auto Repair Services: Keeping Your Vehicle Road-Ready

Unleashing Creativity with Vidnoz: The Best Free AI Video Generator in 2025

The Connection Between Air Drying and Energy Efficiency in Industrial Settings