One of the dominant trends in 2022 is the coming of age of “smart manufacturing,” which combines automation with artificial intelligence and machine learning to help manufacturers to strengthen the bottom line – or simply to stay in business.

“The race to improve quality through digitalization is hitting critical mass. Suppliers utilizing quality management solutions like those available from Plex, which offer real-time, repeatable, predictable quality can help these manufacturers by delivering superior components that reduce their overall risk exposure and support market share expansion,” says Reid Paquin, Research Director at IDC.

Plex Systems, a Rockwell Automation company, is a leader in cloud-delivered smart manufacturing solutions. Its platform gives manufacturers the ability to connect, automate, track, and analyze every aspect of their business to drive transformation.

This includes the updated Ford Motor Company Customer-Specific Requirements for IATF 16949:2016. “Plex is proud that automotive suppliers can start realizing the transformative benefits of our quality management solution (QMS). We’re focused on maintaining strong connections to the industry and regulatory bodies and actively engaging with customers to help deliver results-driven solutions that assist with meeting these new standards as well as reduce cost to comply,” said Anthony Murphy, Vice President, Product Management, Plex in September 2022 media release.

Plex provides flexible software-as-a-service (SaaS) solutions and is well known for its extensive capabilities and closed loop quality process. Plex QMS follows a plan-do-check-act methodology to drive the full quality lifecycle, enabling manufacturers to deliver better margin and drive a culture of quality.

The solution also helps companies meet the newest IATF-16949 FMEA requirement, with support for foundation FMEAs, and automated FMEA information flows from a Part FMEA to the control plan. The cloud-based Plex QMS also ensures all users are accessing the same Process FMEA (PFMEA) version, says the company.

Automotive Industries (AI) asked Anthony Murphy, Vice President Product Management, Plex, how manufacturing is adapting to meet the challenges of a dynamic global market-place.

Murphy: Manufacturers have always strived to improve margin and ROI through efficiency and elimination of waste and redundancies. With the acceleration of trends like digitization, remote work, right-shoring, and skilled labor shortages, manufacturers have changed many of their heritage approaches.

In our 7th annual study “State of Smart Manufacturing” global report, which surveyed more than 300 manufacturers in a variety of industries including automotive, aerospace, food and beverage, electronics, consumer goods, plastics and rubber, precision metal forming, and more, we found that an overwhelming majority (83%) believe smart manufacturing is a key to their organization’s future success.

The installed base of operations technology (OT) in manufacturing environments is often heterogeneous and includes a combination of legacy and modern technologies. Plex helps manufacturers solve these challenges with a complete set of digital solutions that drive consistency by consolidating disparate systems, enabling full automation and integration of data and processes from the shop floor to the top floor.

Our manufacturing operations solutions include Production Monitoring, Asset Performance Management (APM), Quality Management (QMS), and Manufacturing Execution System (MES). These solutions enable manufacturers to streamline operations, eliminate cost, but also provide access to leading technology – in a pragmatic & ‘ROI First’ fashion – without costly upgrades or reimplementation.

AI: What are some of the highlights of your SaaS offerings?

Murphy: Earlier in 2022, we introduced several innovations in our SaaS offering to support customers’ ability to realize the benefits of digitalization in the evolving manufacturing and supply chain landscape.

For example, we offered additional modularization of the Plex Smart Manufacturing Platform with new levels of flexibility and quick implementation providing more granular, cloud-native capabilities.

Manufacturers can start their journey with base applications like MES or quality management and seamlessly add cloud-native module packages – for example tooling or advanced quality – when needed.

Customers integrating the Plex Smart Manufacturing Platform have achieved significant operational gains with regard to better than world-class PPM, increased inventory accuracy, improving on-time shipments, lower scrap rates and overall improved operational efficiency.

“Now we are addressing issues that go right to our bottom line because we have valuable details that we never had before. We can click a button and it’s right in front of us. Once we focused on real information, we started managing the stuff that matters,” said a Plex customer.

Plex introduced machine learning to improve demand forecasting and advance automation for manufacturers’ supply chain planning. Through advanced pattern recognition that delivers deeper insights, organizations can improve demand forecasting accuracy, further drive predictable execution, and lower operating costs. We’ve seen improvement of up to 10% over traditional exponential forecasting smoothing models.

AI: What makes your software so flexible?

Murphy: The manufacturing industry is dynamic and constantly changing. Businesses yesterday may have been classified as single component automotive supplier, making and shipping body panels to an OEM, or example.

Today, they would be considered a fully integrated supplier: sourcing material, producing multiple components, assembling and shipping full assemblies to the OEM, with plants globally. While diversifying your manufacturing business to account for new trends like EVs and expanding to other markets outside of automotive is very attractive to business owners, this transition requires a digital transformation.

Plex is built with flexibility by design so that a solution can be quickly deployed and configured to meet the specific plant needs. Additionally, customers can set up individual work centers in the same plant to behave differently, based on the individual products produced.

This modular configuration coupled with our multi-tenant SaaS model gives manufacturers a completely elastic solution that scales up and down to meet their needs regardless of size, geography, business model, modes of manufacturing, or industry, increasing levels of automation from the plant down to the work center.

Most customers run on our best-in-class private cloud, but to add flexibility and support customers with European data residency requirements, Rockwell Automation announced the availability of Plex on the Microsoft Azure cloud in Europe. This allows customers to leverage the power and scale provided by Azure in-region and is aligned with the ongoing partnership between Rockwell Automation and Microsoft.

AI: How did the Covid 19 pandemic impact manufacturing and in turn, how did Plex adapt to manufacturers’ new requirements?

Murphy: Covid accelerated trends like digitization and exacerbated issues like skilled labor shortage and supply chain. Since Plex customers were running their systems in the cloud they continued to have access to all of their manufacturing data wherever they were working.

This resulted in minimal business disruption and a rapid return to normal operations as manufacturing rebounded. In parallel, workforce shortages impacted availability of resources. However, manufacturers with digital operational technology systems in place fared better than those competitors that were operating on paper-based, manual processes.

As far as supply chain, the days of steady and dependable supply chains that enable long-term lean and just-in-time replenishment to manage costs are gone. Businesses now understand that planning and forecasting must include the assumption of disruption and rely on data to navigate this new normal.

Adding machine learning to Plex DemandCaster Supply Chain Planning empowers customers to overcome supply planning challenges, digitally transform their planning, and provides machine-powered insights.

By infusing the sales forecasting process with machine learning, customers can bring in a wealth of additional data as an input to the forecasting process that a human nor traditional statistical forecasting methods can discern.

These additional inputs are used to help calculate and recalibrate the process to improve forecast accuracy.

Synergy with Rockwell Automation

Rockwell Automation acquired Plex in September 2021.

Since then, there have been a number of customers added to the two companies portfolios thanks to the synergy between the two.

For example, shortly after the acquisition, Plex’s cloud-native MES was chosen by REE Automotive, an automotive technology leader and provider of electric vehicle (EV) platforms.

“REE Automotive is benefiting from using Rockwell Automation for its line-side controls and is now looking to create even greater efficiencies and savings through this MES deployment. Plex MES will underpin REE’s highly digitalized manufacturing operations in the UK and US as the company prepares for full-scale production in 2023,” said a Rockwell executive in 2022.

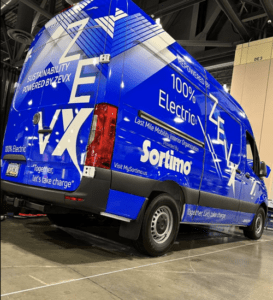

ZEVx, has selected Plex Manufacturing Execution System (MES) to drive production of its electrification solutions. The selection of Plex followed the signing of a strategic three-year partnership between ZEVx and Rockwell Automation in April 2022.

ZEVx builds and designs battery electric power systems and data intelligence for e-mobility applications.

The two companies agreed to work together to use advanced technology to accelerate the adoption of electric vehicles (EVs).

ZEVx, specializes in the electrification of small and medium duty fleet vehicles, converting its customers’ customized internal combustion engines (ICE) to EVs in one day.

By leveraging Rockwell Automation’s solutions and a network of legacy automotive service partners, ZEVx will be able to assemble specialized kits for their customers’ fleets to accelerate the pace of conversions.

“The addition of Plex MES as a part of our Rockwell Automation collaboration will allow us to accelerate battery electric power systems strategy. Plex’s heritage in smart manufacturing technologies for the automotive industry, including functionality related to supplier and inventory management, were central to our selection.

“The Plex technology is integral to ZEVx’s scalability and agility on our path to becoming the leader in battery electric power systems and data intelligence for e-mobility applications,” said Charles Maury, founder and chief data officer, ZEVx in a September 2022 media release.

Added Luca De Ferrari, vice president, Information Solutions, Americas at Rockwell Automation: “The automation of traceability and quality processes enabled by Plex MES will allow ZEVx to eliminate paper-based, time-consuming manual processes while unlocking real-time decision making. ZEVx is establishing a smart battery electric power systems foundation which will help them achieve a competitive advantage.”

More Stories

Towing Services Explained: 6 Key Facts You Need to Know

Environmental Factors That Influence Ceramic Coating Choices

Best Wheel Size for Off-Road Adventures: What People Get Wrong