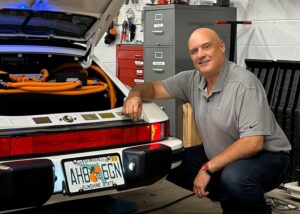

Low-volume electric vehicle manufacturers can now deliver replica vehicles classified as “new” in the United States following a design breakthrough by Southfield Classics.

The company worked closely with SEMA Garage to meet United States government regulations on low-volume vehicle manufacturing guidelines, including regulations of propulsion system requirements mandated by the NHTSA, EPA, and CARB.

The integration of Ampere EV’s Atom Drive EV Powertrain on Southfield Classics low-volume replica chassis allows Southfield and companies using the Southfield Replica Chassis to manufacture classic vehicles certified as new. The chassis underpins the company’s SC31T Chevy 3100 restomod pickups, in addition to other chassis that

the company expects to achieve certification in the near future.

“Federal Certification of this chassis and powertrain means that low-volume builders can leverage the same opportunities as major OEMs, making these vehicles easier to manufacture more readily available to passionate enthusiasts,” says Ampere EV CEO Matt White.

Automotive Industries (AI) asked White how scalable the company’s production is of the Atom Drive EV system (for series production, for example).

White: Our goal from inception has been to scale using industry-proven technologies and integrate them safely and efficiently. We have designed the Atom Drive EV Powertrain to minimize installation time, regardless of the chassis type, making it ideal for restorations and fleet repowering.

We can quickly supply what our customers need, while continuously adding options through smart-managed company and system growth. We now have a proven record of accomplishments, evidenced by the ability to satisfy our customers’ needs.

We can also obtain financing should we need to grow more quickly than our organic funding, which has supported us in our first three years of business.

AI: What support do you provide for independent coach builders?

White: Our support model consists of two paths; B-to-B and B-to-C. Our B-to-B support model utilizes a ticket system that allows our customers to clearly communicate with our engineers and support staff to seamlessly document requests and responses. It’s highly efficient, and the proof of its success is evidenced by the feedback we have received about it from our customers.

To address B-to-C support, we engaged a global leader in the aftermarket EV space, Legacy EV. It can supply builders with Atom Drive systems and provide them with technical education and product support.

Leveraging our relationship with Legacy EV allows us to utilize their experience dealing with individual builders, including the specific needs associated with that customer base, and allows us to focus on our high-volume and fleet customer base.

From an installation standpoint, we provide robust documentation for all the components and include thorough instructions on installation procedures. This dramatically reduces installation times, meaning builders can build more cars, and fleets can quickly repower their vehicles and reap the benefits of these conversions.

With basic EV system knowledge, an experienced installer can install an Atom Drive system in days, not weeks. For example, at the 2024 SEMA Show, three installers who had never installed an Atom Drive – one of whom was a recent graduate of Legacy EV’s training program – installed a complete system into a vehicle in under 10 hours. The chassis rolled into the show under manpower and drove out under its own power.

AI: Is there a market outside of the United States for your drive systems?

White: Without a doubt, there is a market outside of the United States. Although it is not our primary focus, we are mindful of the international market, while also being aware that international tariffs will drive our ability to sell and compete in a global market.

The North American market is ripe, however. As parts for classic cars become more difficult to source, and as classic vehicle owners seek more performance, reliability, modern technology and conveniences, there is tremendous growth in the hot rod and classic car restoration market.

Southfield Classics’ chassis accelerates the ability for more builders to safely and reliably choose this path.

From a repowering perspective, there are a multitude of use cases that warrant converting light and medium-duty vehicles with relatively fixed drive cycles to electric. If the goal is to reduce emissions in urban environments and reduce costs associated with the purchase of new specialty vehicles, then the Atom Drive is positioned strongly to solve the repowering needs of fleets.

AI followed up with Dan Paul, General Manager of Southfield Classics, asking him to share some of the company’s plans based on the powertrain and platform.

Paul: We are currently working on several cool projects for 2025. Just a small hint, we currently are finalizing our design for our Race and Street versions of an all-electric iconic American racecar. Plus, we are staging up for an antique suburban Show truck.

AI: Is the chassis available to other coachbuilders?

Paul: Yes, it is available to other coachbuilders as a complete turnkey chassis EPA range tested and certified and will be sold with MSO. In 2025, we will offer a limited run.

AI: How will you meet the anticipated demand?

Paul: We have set up our facility as a manufacturer and will be pulling chassis from our line as necessary to meet demand.

AI: What is the appeal of a classic electric vehicle?

Paul: The only drawback to new electric vehicles is styling. We intend to unite classic styling with modern drivetrain technology. Our all-new replica looks like the iconic designed vehicles of the past but is mated with all new parts and all new modern advancements in electric technology.

Andrew Fillingim, Lead Software Engineer at Ampere EV, was asked whether vehicle assemblers can customize the Atom Drive software.

Fillingim: Our software can be customized, but not by installers. We own and develop the Vehicle Control Unit (VCU) software and have performed all the calibration development for the powertrain and system.

These calibrations are validated through extensive bench and road testing. The Atom Drive Powertrain is calibrated to work with multiple motors and components, ensuring that all the parts work together as a system. This leaves the installer to focus only on the installation, with the confidence that it will work seamlessly when the installation is completed.

However, we allow the installer to select how the user interacts and controls our system. Our software allows the assembler to select and enable different user interfaces for the vehicle, such as using the main GUI to control AC/Heat, versus having physical switches. The installer also can fine-tune the driveability of the powertrain to meet the uniqueness of the build.

In addition, we are equipped to perform rapid software development, which means we can add new features for customers ordering our kits, based on any specific needs for their application. The Ampere EV team is continuously updating the Atom Drive software with new features and to support new components.

AI: Does it provide options such as over-the-air updates, and value-added services?

Fillingim: The Atom Drive system supports over-the-air diagnostics to remotely diagnose system faults. For fleet applications, this includes telemetry that allows fleet managers to monitor fleet usage.

We also provide fully featured OBD2 diagnostics, so that the installer and user can read fault codes through the GUI, or an off-the-shelf OBD2 scanner. We are releasing over-the-air system updates in 2025.

AI: How close are we to software-defined custom low-volume electric vehicles?

Fillingim: We take a software-defined approach to the Atom Drive EV powertrain, so it’s happening now. Core hardware used in our system is consistent, and the control of these components is integrated into our VCU, which enables all our features and functionality to exist through the software. This allows customers who already have Atom Drive-powered vehicles on the road to implement updates and benefit from new software features and functionality.

Contact: Ampere EV

Website: www.ampereev.com

Inquiries: https://ampereev.com/contact/

More Stories

Auto Repair Services: Keeping Your Vehicle Road-Ready

Unleashing Creativity with Vidnoz: The Best Free AI Video Generator in 2025

The Connection Between Air Drying and Energy Efficiency in Industrial Settings