Every freight and passenger-carrying vehicle is expected to soon be in real time communication with distributed cloud-enabled network control centers through the Internet of Moving Things (IOMT).

IT consulting leader Syntel says that, because of this trend, it has become imperative for automotive manufacturers and logistics and transportation service providers to have a transparent view of their supply chains, systems and processes in real time. They need to cater for omni-channel business models and to drive business and operational efficiency to stay competitive.

Syntel collaborates with leading manufacturing and logistics companies to deliver efficient IT solutions for vehicle monitoring, warehouse management, inventory management, finance and revenue management, customer relationship management, distribution, marketing and sales, 3PL and 4PL, freight, cargo, and transportation management and enterprise services.

Based on its experience and lessons learned from developing various IoT solutions, Syntel has developed an IoT platform called Connect One. Syntel is currently working with a leading medium and heavy duty commercial vehicle manufacturer to enable real-time monitoring of sensors embedded in more than 50,000 of its vehicles in the field. The objective is to remotely assess the wear and tear on vehicle parts and use analytics to plan maintenance operations. The vehicle’s sensors and on-board computers generate a stream of data, including fault codes, temperature and pressure readings, GPS coordinates, part numbers and VIN numbers. These data streams arrive in a variety of different formats and protocols, which are aggregated and processed in real time by Syntel’s Connect One analytical engine.

Organizations can use the library to select or build an IoT platform by integrating various custom and off-the-shelf components. All components in the reference architecture are loosely coupled, enabling organizations to add components incrementally as the complexity of their business requirements increases. The reference architecture can also be used on multiple platforms such as MS Azure IoT, AWS IoT, IBM Bluemix, IBM WebSphere and Tibco Fast Data. Connect One for Manufacturing incorporates a big data platform to receive streaming data from vehicle sensors and on-board computers, an analytical engine to generate insights in real time, and a multi-channel notification engine.

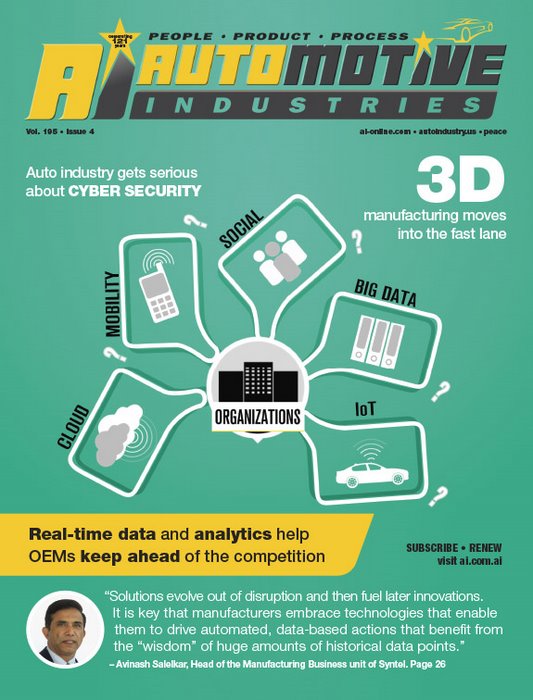

Automotive Industries (AI) asked Avinash Salelkar, Head of the Manufacturing Business unit at Syntel, how the key trends of automation, big data and IoT are transforming the automotive industry.

Salelkar: While each of these trends would have brought about significant benefits, maturity in all three has created the perfect storm that is going to transform our lives in the near future. Intelligent automation is one of the most disruptive forces IT and business process operations have seen, as it is about decoupling routine service delivery from labor. The ability to have devices create and consume data has led to multiple opportunities in terms of connected equipment, connected cars and connected appliances. The IoT has provided the ability to sense and control remotely.

Automation actually started on factory shop floors and routine and dangerous tasks were the first candidates. While the general perception is that automation reduces costs, the fact of the matter is that collateral benefits like improved repeatability, accuracy, productivity and higher safety are equally if not more important.. Recently, automation has started entering the IT space and we see benefits around cost savings and improvements in productivity.

The amount of data generated by connected things would have overwhelmed humans if not for advances in our ability to manage and process huge swaths of data through big data solutions. We are now able to sense, transmit and receive data and then analyze that data through artificial intelligence and machine learning to take automated decisions and actions.

AI: Are automotive companies beginning to act like IT companies, with new business units for mobility and digital services?

Salelkar: Absolutely. Being in the motor vehicle business is no longer just about making and selling cars. It is now about providing an engaging customer experience. Auto companies now face threats from ride sharing companies. Cars now have more software embedded than early spacecraft did. So IT is not only central to the product, but to the entire process of making the product. And more so to the process of getting the product to the end customer and ensuring that it delivers the expected value.

AI: Cars will ultimately communicate, socialize and collaborate with other things, including other vehicles, traffic lights, parking bays and retailers, thereby becoming a participant in a wider network of systems – what role will Syntel play in this future?

Salelkar: If one breaks up the entire process of activities that occur there are multiple discrete activities that happen in tandem. To start with, there is the sensing and generation of data. Then the data is transmitted, managed, and transformed to generate information, which then can be analyzed to help decide on actions. The action then has to be transmitted and executed. Syntel’s role is in the management of data and the analytics, and the decision-making and automation that follows.

AI: How has your company helped OEMs keep up with these latest trends?

Salelkar: Syntel works with automotive manufacturers to enable real-time monitoring products through embedded sensors to remotely assess the wear and tear on critical parts and using analytics to plan maintenance before a critical failure takes place. OEMs incur high costs due to sudden part failures in vehicles. There is also a high dependency on SMEs to diagnose the fault and suggest the next best action. Existing platforms in the market were not scalable to support high volume of ingress events.

Syntel’s Connect One for Automotive combines a Big Data platform to receive streaming data from vehicle sensors and on-board computers, an analytical engine to generate insights in real time, and a messaging publisher for action notifications. Data streams from vehicle sensors combined with environmental data are aggregated and processed by Connect One’s analytical engine. Real-time analytics are performed on the stream of incoming data, and business rules assess and recommend corrective action. This enables manufacturers to monitor and detect faults earlier than ever before, driving preventive actions, reducing warranty costs and improving customer service.

SyntBots is very useful on the IT side by improving productivity and delivering direct business benefits through automation of ITOps, DevOps and BizOps. At the back end, Syntel’s legacy modernization services employ deploy recursive automation to help reduce operation costs by more than 30% and improve business productivity by more than 70% by modernizing integrated manufacturing and control systems.

AI: How can Syntel help OEMs master the challenges of sophisticated sensor and telematics systems?

Salelkar: The area of data management and analytics is evolving rapidly and Syntel is at the cutting edge through the work it is doing on connected devices. Our Connect One platform enables signal processing from variety of smart sensors, devices and wearables, for both moving and fixed equipment or machinery. Syntel is leveraging its preventive maintenance solutions developed on a highly scalable next generation telematics platforms and specific algorithms that make sense of data streams from multiple sensors in real time.

AI: Why is it important for OEMs to have real-time visibility of information from the field?

Salelkar: Data and analytics are becoming the key to servicing digital customers. Whether it is the ability to use data to autonomously drive vehicles, predict failures before they occur, or even help connect with and do business with digital customers, the key is to have the ability to access and process data intelligently.

AI: Can digital solutions keep pace with the digital disruption that is transforming the industry?

Salelkar: Digital solutions work in tandem with digital disruption, one feeding off the other. Solutions evolve out of disruption and then fuel later innovations. It is key that manufacturers embrace technologies that enable them to drive automated, data-based actions that benefit from the “wisdom” of huge amounts of historical data points.

More Stories

What You Should Know Before Filing a Car Accident Claim

Injured in a Car Accident in St. Louis? Here’s What to Do Next

Historic Sportscar Racing (HSR) and Goodyear Announce Multi-Year Partnership