Model Smart Factory Elements supports manufacturing companies to purposefully implement the plan of a smart factory

Small lot sizes, short delivery times: Increased requirements in production present manufacturing companies with new challenges. MPDV’s Smart Factory Elements model supports companies in successfully meeting these challenges and turning the vision of a Smart Factory into reality.

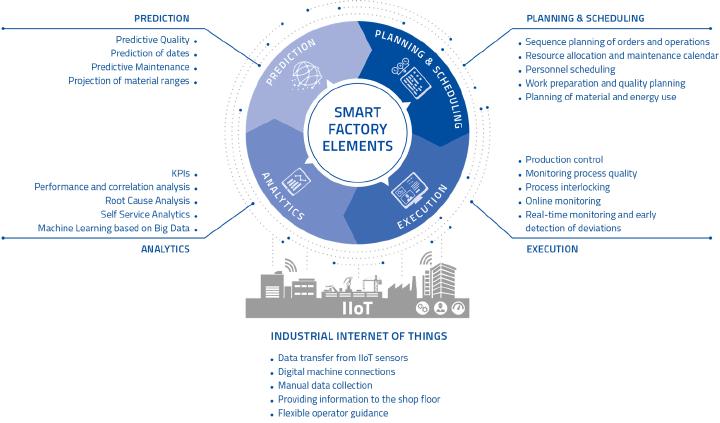

The Planning & Scheduling element symbolizes the planning capability of production in terms of resources, time and maintenance. The specifications can be efficiently implemented and documented. The Execution element represents this. Based on the collected data, analyses can be created to check whether the figures are met and to identify potentials for optimization (Analytics). For example, the analyses are used to make predictions about how likely a malfunction is or when maintenance is necessary again (prediction). The Industrial Internet of Things (IIoT) collects data and provides these.

The five elements of MPDV’s Smart Factory Elements model help to implement the plan of a Smart Factory in a specific way. MPDV’s model makes a significant contribution to the successful transformation of manufacturing companies into Smart Factories.

Learn more about MPDV’s Smart Factory Elements model in this video: http://mpdv.info/prsfevideo

MPDV Mikrolab GmbH

MPDV headquartered in Mosbach, Germany, is the market leader of IT solutions for the production sector. With more than 40 years of project experience in the production environment, MPDV has extensive expertise and supports companies of all sizes on their way to the Smart Factory. Products such as the Manufacturing Execution System (MES) HYDRA by MPDV or the Manufacturing Integration Platform (MIP) enable production companies to streamline their processes and stay one step ahead of the competition. The systems can be deployed to record and evaluate production-related data along the entire value chain in real time. If the production process is delayed, employees can instantly detect the problem and take proactive measures. More than 900,000 people in over 1,400 production companies worldwide use MPDV’s innovative software solutions every day. These include renowned companies from all industries. MPDV currently employs 500 people at 13 sites in Germany, China, Luxembourg, Malaysia, Switzerland, Singapore and the USA. For more information www.mpdv.com .

More Stories

Sonatus – The industry is shifting gears to software

Cybord warns of dangers of the stability illusion

HERE building trust in ADAS systems