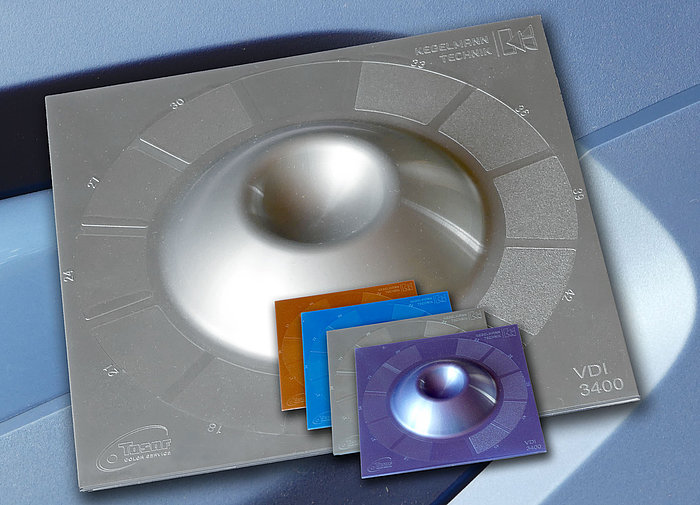

The new metallic color masterbatches from Tosaf Color Service put an end to the previously typical and undesirable streaks and similar surface defects on plastic parts. The key to this lies in the manufacturer’s compounding know-how acquired over the last few decades in combination with the special effect pigments with a rheologically optimized geometry that have only recently become available. As a result, these masterbatches meet the requirements for the cost-cutting, environmentally friendly use of components with brilliant metallic finishes in visible areas. The new masterbatches are available on different carrier systems and, at short notice, in customized shades. They are suitable for all transparent thermoplastics, whereby the brilliance increases with the degree of transparency. They can, however, also be used in opaque plastics such as PC/ABS or PA/ABS blends.

The further developed pigment technology makes a major contribution to the considerable reduction in the separation effects that are responsible for streak formation or color deviations, especially in critical areas such as weld lines, cross-sectional transitions or with distinctly three-dimensional, concave or convex contours. The main beneficiaries of this are suppliers to the automotive industry and other segments with extremely high quality demands and with rapidly changing designs that are geared to individuality.

Depending on the demands, moldings produced with this masterbatch stand out through their color depth and outstanding surface gloss and also through a delicate structure when eroded molds are used. In many applications, they can replace coated or electroplated parts, which not only saves costs through the elimination of additional work steps, but also makes a considerable contribution to the preservation of the environment. Added to this is the good suitability of the single-sort parts for recycling

Andreas Kruschinski, head of Sales and Marketing at Tosaf Color Service, comments as follows: “These new special effect masterbatches are our response to a variety of demands from our customers that could previously not be met in this combination and to such perfection. For us, the most promising markets apart from automotive interior and exterior applications are office electronics, for example keyboards and laptop housings, as well as white goods in the form of large and small kitchen devices.”

Tosaf Color Service is a pioneer in the field of masterbatches and has been developing innovative products and services in plastics coloring since 1970. Its broad range of products covers standard colors, additives and combination solutions that meet not only all kinds of customized color requirements but also satisfy the related functional challenges. Tosaf Color Service is a subsidiary company of Tosaf.

Tosaf, Alon Tavor/Israel, has been developing and producing high-quality additives, compounds and color masterbatches for the plastics industry for more than three decades. Through the continuous expansion of its product portfolio, its production capacities and its regional coverage, it has become a global, market-oriented organization. With more than 1,000 employees in production facilities, warehouses and sales offices distributed around the world, Tosaf now serves customers in more than 50 countries in Europe, North and South America, Asia and the Middle East.

More Stories

How Modern Power Management Enhances Connected Fleet Tech

Automotive Industries (AI) Newsletter April 2025

Bangkok International Motor Show 2025 – The Talk of Sensuous Automotive