The world is going green with various methods to lower harmful emissions, and industries across the board are making the necessary changes to keep up. Belt Technologies Inc., a manufacturer of custom metal belt conveyer solutions and conveyor systems for more than five decades, is providing a crucial service for vehicle battery manufacturers as their demands shift from lead acid to electric.

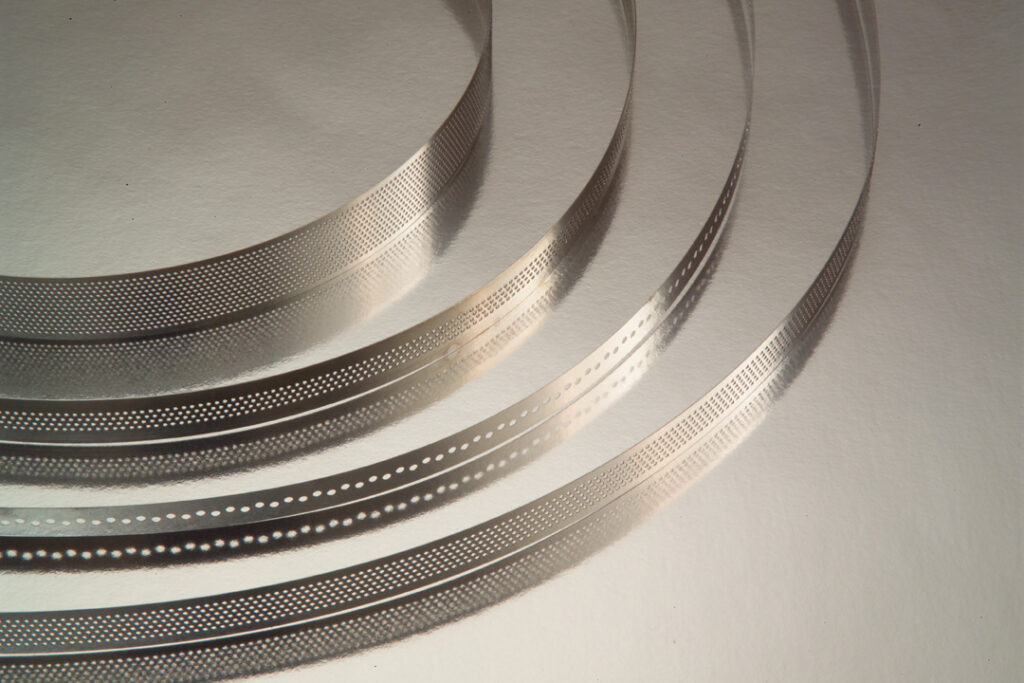

The unique properties and benefits of stainless steel have long made metal belts ideal for automated battery production equipment. Battery components must be transported smoothly and reliably through several production stages, including pasting, filling, assembly, cleaning and pin engraving. Unlike rubber or neoprene alternatives, metal belts provide positional accuracy, smooth motion control and, most importantly, chemical resistance.

“One of our clients is producing approximately 250,000 batteries per shift—you can imagine the wear and tear that would cause on a traditional belt,” said Denis Gagnon, Belt Technologies CEO. “This same client is seeing a dramatic shift in demand for electric batteries and is able to match that demand with a metal belt conveyor system.”

For the automotive industry, the shift is about to pick up speed—multiple states, including Massachusetts <https://www.mass.gov/doc/ma-2

“Many facilities are in a position which will soon require major production changes, and we can help provide them. We don’t offer one-size-fits-all solutions: our engineering team is known for its versatility, designing and building custom solutions for any existing system our clients can provide,” Gagnon added.

For decades, battery manufacturers have trusted stainless steel belts to operate in clean-room environments and resist chemical corrosion for a more reliable, longer-lasting conveyor system. Belt Technologies President Alan Wosky does not expect that to change any time soon.

“Stainless steel has always been the gold standard for lead acid, lithium-ion and nickel batteries,” explained Wosky. “Belt was and continues to aid in traditional battery production, but as the world now moves in a new direction, it’s exciting that we’re able to remain a part of this new process for electric vehicle batteries as well.”

In addition to the battery industry, Belt Technologies’ metal belts and conveyor systems are used in 3D printing, robotics, medical manufacturing, food production and much more. For more information about Belt Technologies, visit belttechnologies.com

About Belt Technologies

Belt Technologies, Inc. has been producing custom metal belt conveyor solutions for new and existing conveyor systems for more than five decades. Sophisticated engineering, advanced manufacturing processes, and an unlimited variety of configurations and coatings are available to custom-design belts to suit any application. Metal belts, timing belts, and metal drive tapes are superior, high-quality options for automated production and robotic facilities. To learn more about Belt Technologies and metal conveyor belts, visit belttechnologies.com

More Stories

What You Should Know Before Filing a Car Accident Claim

Injured in a Car Accident in St. Louis? Here’s What to Do Next

Historic Sportscar Racing (HSR) and Goodyear Announce Multi-Year Partnership