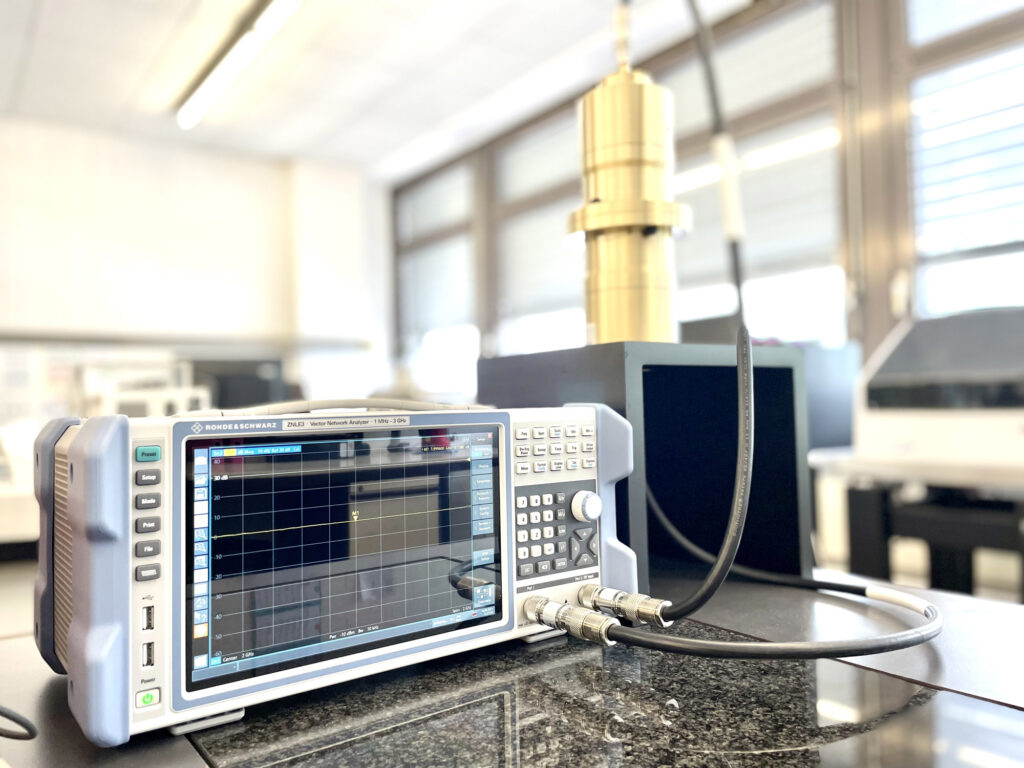

Image: Testing cell for measuring electromagnetic shielding effectiveness according to ASTM D4935-18 at Datwyler lab.

Datwyler is expanding its in-house capabilities through a focus on Electrically and Thermally Conductive and Electromagnetic Interference (EMI) Shielding Materials (ETEMI™). Project ETEMI™ was launched in 2020 to address challenges in applications related to new mobility and beyond, with a material development scope covering conventional elastomers, liquid silicon rubber (LSR) and thermoplastics. The aim is to ensure that customers diversifying towards hybrid and battery electric vehicles are able to realize the full potential of system critical sealing components with enhanced functionality – such as sensing seal integrity or keeping electrical charge locally in a battery gasket, for example.

Luana Lettieri, Manager Material Development, at Datwyler, commented: “As the trend towards electrification continues to gather momentum, the ability to conduct electricity and heat, as well as to shield certain components from electromagnetic signals, is increasingly important. Project ETEMI™ is the driving force behind the creation of an entirely new category of materials – those designed to fulfil the highest requirements in terms of sealing technology, in addition to delivering the aforementioned capabilities in a safe and efficient manner.”

Ultimately, ETEMI™ will be the catalyst for the creation of a material matrix whereby electrical and thermal conductivity and EMI shielding can be coupled and decoupled to suit a wide variety of applications. The thermal management of an electric vehicle battery could be managed in part by its sealing material, for example, while EMI shielding could likewise be introduced via sealing technology to safeguard components such as sensors and critical control units from environmental effects as well as electromagnetic interference.

Electrical conductivity for discharging and antistatic materials is also possible via sealing technology, and there are many examples of this combined functionality enabling certain components to be removed – such as metal conductors – thus delivering weight reduction benefits. Overall, the key objective is to balance the ability to provide a high-performance seal with the need to meet the many additional requirements arising from electrification.

Advanced material development capabilities

The ETEMI™ project has seen Datwyler’s capabilities advance in a number of areas, including the mixing of specialist compounds using in-house mixing equipment and specifically designed mixing programs, and also the ability to comprehensively analyze and test new materials. Many of the challenges presented to the company as electrification projects develop will not have been experienced before, and new materials in this space must comply with regulations that are more stringent than ever before. As a result, in-house laboratories have been equipped with the expertise and technology required to develop and test compounds to the very highest levels of regulated norms, such as ISO 1853 and ASTM D911 for electrical conductivity, ASTM D4935-18 to analyze EMI shielding effectiveness or DIN EN 993-15 to characterize thermal conductivity of developed compounds.

Hediyeh Zahabi PhD, Manager Material Development at Datwyler, added: “Projects such as ETEMI™ are generally undertaken at an academic level – focusing on a single challenge or use case. By taking the initiative in-house and leveraging our material expertise, we are able not only to create, test and analyze a wide range of new materials based on emerging new mobility challenges, but also to apply our strengths on the industrial side of the business to ensure those materials can move from the laboratory to large scale serial production quickly and efficiently. The project has pushed us as a business to evolve our knowledge as well as our portfolio, ensuring we can continue to work on a co-development basis with our customers to create custom solutions based on their ever-changing needs and requirements.”

For more information on Project ETEMI™ or to speak to a Datwyler expert, please contact: materials@datwyler.com

About Datwyler

Datwyler – a leading provider of high-quality, system-critical polymer components

Datwyler focuses on high-quality, system-critical polymer components and has leading positions in attractive global markets such as mobility, healthcare, oil & gas, food & beverage and general industry. With its recognized core competencies and technological leadership, the company delivers added value to customers in the markets it serves. With more than 20 operating companies on four continents, sales in over 100 countries and more than 7,000 employees, Datwyler, headquartered in Switzerland, generates annual sales of more than CHF 1’000 million.

More Stories

Acoustic sensor systems and Fraunhofer measurement technology for in practical testing ͏

OSI Systems Receives $10 Million Order for Cargo and Vehicle Inspection Systems

Mitsubishi Electric Automotive America Launches Guardian Generation 3 Trial with Seeing Machines in North America