Luminaires for Vehicle Interiors

The days when automotive lighting consisted of a few instrument cluster lights and the bare minimum in cabin illumination are far in the past. Modern vehicles make extensive use of advanced luminaries for almost every aspect of driver and passenger experiences and interactions. This includes applications like functional instrumentation and data visualization, safety indicators, cabin ambience and accents, and even entertainment. Most, if not all, of these lighting systems are dynamic with numerous control modules and even networked connectivity.

Figure 1 – Modern vehicles use more sophisticated and advanced interior lighting systems, including LED line illumination accents.

It is worth noting that the visual environment of modern automotive interiors is a blend of discrete lighting elements and traditional matrix displays. Hybrid strip lights and miniature light clusters are also usually present. In all of these cases, LED’s have become the standard for high quality lighting as measured by a variety of performance parameters including luminous efficiency, reliability, formfactor, and price.

Critical Performance Parameters

LED lighting has been around for over 60 years as a commonplace electrical component. For automotive applications however, the adoption has been slow but steady. This is due to the stringent requirements placed on these devices by both the manufacturers, who require high reliability at low cost, and the end users, who demand a wide variety of colors and shapes and direct a discerning eye to light and color uniformity. Modern LED’s are able to satisfy all of these requirements and are now ubiquitous in our everyday surroundings.

Luminous efficiency and brightness sit at the core of qualifying LED performance. The physics of generating light in an LED is based on electroluminescence, the emission of photons when electrical current is induced through a junction of dissimilar semiconductor materials. The physical nature of these semiconductors, the dimensions and design of the LED structure, and the optical properties of the surrounding enclosure all affect the ratio of emitted light to electrical current. This ratio is typically expressed as the coefficient of luminous efficiency. For reference, a generic incandescent lightbulb is capable of emitting around 15 lumens of light per watt of electrical power (lm/W). Modern LED’s are now in the range of 18-22 (lm/W). In addition to pure optical output, it is important to recognize that the human eye perceives brightness differently across the spectrum of visible colors. A more practical measurement that takes this into account is the efficacy, also measured in lumens per watt but scaled using luminosity curves. For automotive applications, LED’s might be extremely high power, as in the case of headlights, or relatively low power, for accent lighting or simple indicators. In each case, the range of available colors, total optical output, and luminous efficacy are important in the design implementation.

Depending on power and space requirements, LED’s are now available in a wide variety of electrical packages ranging from miniscule surface mount styles (SMT) to larger socketed bulbs that mimic traditional incandescent solutions. LED package selection is not just a matter of form factor and thermal dissipation. Different packaging technologies are used to protect the LED from the environment, enhance manufacturability, control direction and angle of emitted light, and even alter the characteristics of emitted light through the use of fluorescent materials. Several examples are shown in the figure below.

Figure 2 – LED package varieties – Source: Rohm

Environmental protection of the LED is especially critical for automotive applications. In order to guarantee operation in extremely harsh environments over long periods of time, devices are required to meet the AEC-Q102 automotive qualification standard. This standard stresses the LED in numerous ways ranging from temperature and humidity to shock and salt exposure, ensuring reliable operation for the lifetime of the vehicle with a focus on the safety of the passenger.

As the complexity of automotive interiors has increased, so has the expectation of the driver and passenger for extremely high levels of refinement. From the lighting perspective, this implies tightly controlled parameters for color mixing and uniformity, especially in low light situations where the variation sensitivity of the human eye is heightened. For example, a strip light composed of a series of multi-color LED’s must all be within a very tight tolerance for output power of each color channel at a given current, or else the effect of a single illuminated geometry will be lost. To this end, diffusers and lenses are incorporated into automotive LED packages to aid in color mixing and surface uniformity.

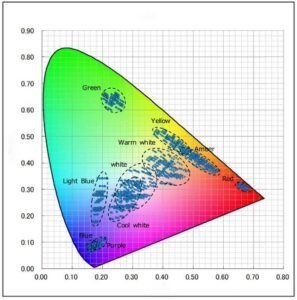

Color mixing is of particular importance when considering products that rely on uniform white illumination. Typically, LED’s are given a manufacturing tolerance for luminous output across a range of wavelengths. As shown on the left in the figure below, blue, green, and red LEDs each have an acceptable level of variability that is screened during the production process. This does not, however, provide any quality control for the uniformity of white illumination, which consists of all three LEDs being active at the same time. To achieve high quality controlled white light, a more advanced screening process must be used, called “white binning”. As shown on the right side of the figure, the tolerance of each constituent LED is tightened to guarantee that the white combination stays within a defined variability boundary.

Figure 3 – White sorting tightens requirements on individual RGB colors. Source: Rohm

ROHM’s SMLVN6RGBFU

To meet the complex needs of the modern automotive lighting designs, ROHM has developed the SMLVN6RGBFU1 line of RGB devices. Shown in the figure below, these LEDs offer high brightness, excellent color mixing, and precise color binning in an industry leading 0.6mm thick SMT package.

Figure4 – ROHM’s new SMLVN6RGBFU1 meets the needs of modern automotive illumination

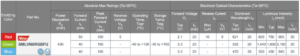

This device is AECQ-102 certified and offers 400mW of power across the -40C to 100C temperature range. Summarized in the table below, each of the three constituent LED’s are optimized to wavelength and optical efficacy.

Figure 5 – SMLVN6RGBFU characteristics. Source: Rohm.

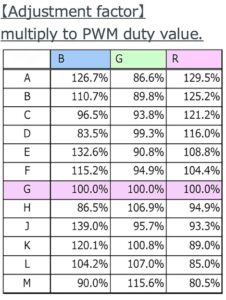

LED’s such as this are often driven with a pulse width modulated (PWM) controller to adjust the forward current and in turn, the color and brightness. ROHM offers a unique simulation tool that allows the designer to apply an adjustment factor to the PWM signal for the purposes of color binning. An example is shown in the table below, where the PWM adjustment factor is listed for each of the LED’s for a particular device grouping. A total of 12 color bins (ranks) are provided and the resulting adjustment factors allow for the potential elimination of color calibration during production.

Figure 6 – Example adjustment factor table

By using these adjustment factors, the variability of color for 10 predefined values can be reduced to incredibly small levels. This is depicted in the figure below, where a stock LED is driven directly using standard PWM on the left, and the same LED is then driven with adjusted PWM factors on the right. For each predefined color, the variability is significantly improved, especially in the white categories. As a result, these LEDs are capable of generating exquisite visual effects and precise illumination for even the most demanding of vehicle interiors. For colors other than white, custom binning solutions can be provided to achieve the same level of variability.

Figure 7 – Traditional color variation (left) compared to ROHM’s product (right) with white binning and adjustment factor. Source: ?

Conclusions

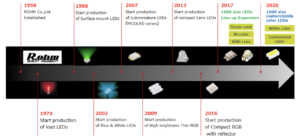

ROHM has a long history of innovation in the field of LED illumination that dates back 1973. Their expertise and past successes has made them an industry leader in LED solutions, and their latest foray into automotive luminaires is yet another example of their commitment to quality and focus on customer needs.

Figure 8 – ROHM’s LED history. Source: Rohm

The SMLVN6RGBFU is only one example of a ROHM LED product with automotive applications. It exhibits best in class luminous efficacy in an ultra compact package while exceeding the environmental requirements for automotive qualification. To learn more about this device or ROHM’s other LED product lines, visit:

https://www.rohm.com/products/led/chip-leds-multi-color-type/smlvn6rgbfu-product#productDetail

More Stories

Professional vs. DIY Tinting: What You Should Know

New updated edition of “PXIMate” reference guide for T&M engineers available from Pickering Interfaces

5 Mistakes That Can Ruin Your Car Accident Claim