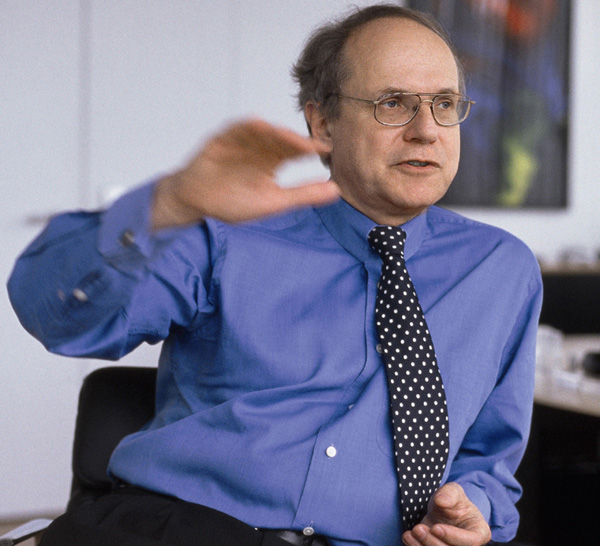

“The core of our brand name is at the same time a BMW brand’s core competence: the development and production of engines.†Burkhard Göschel, Board of Management member for Development and Procurement at BMW AG.

High oil prices are creating opportunities for innovative and new component suppliers which can provide solutions in the quest for alternative sources of energy and more efficient combustion of fossil fuels.

BMW has joined forces with DaimlerChrysler and General Motors in a joint venture for the development of hybrid power concepts. The three companies are expected to invest $100 million or more in the project, which will be in addition to BMW’s own research. The technology to be developed will be of the so-called “2-mode†type,†which allows electric-only operation under some city-driving conditions and uses its electric motors to boost highway performance.

“The creation of a shared technology platform for hybrid drives will allow us to more quickly integrate the best technologies on the market and will therefore exploit and strengthen the innovative potential of all participating companies,†explains Prof. Burkhard Göschel, Board of Management member for Development and Procurement at BMW AG. “Because the technologies will be adapted to the individual vehicle models, the participating brands will retain their distinctive characters.â€

BMW says it has a technological lead in the race for fuel economy because taxation has seen European fuel prices being historically much higher than in the An example of BMW’s “more efficient, more dynamic†philosophy is the 3 Series. The 1990 325i Sedan with automatic transmission had a 2.4-liter 6-cylinder engine developing 168 hp; accelerated from rest to 60 mph in 9.4 sec. and turned in EPA mileage of 18 city/22 highway. Today’s counterpart, the ’06 325i Sedan, with automatic transmission, is larger, roomier, more refined, better equipped and fitted out with more safety features and technology. Yet, it is quicker, doing 0-60 in 7.2 sec, and is rated by the EPA at 21/29 mpg.

Göschel talks to Automotive Industries (AI) about the xDrive all-wheel drive system, starting with how it differs from that of BMW’s competitors.

Göschel: xDrive is the faster system. It is a fully variable 4×4 system which is using all relevant sensor information for driving stability and traction. xDrive delivers this information to the very fast, electronically controlled clutch, which is dividing the torque between front and rear axle. It improves not only the traction but also the dynamic driving behavior. Due to its fast reaction xDrive prevents under steering and over steering

AI: Which future model series and different models will be equipped with it?

Göschel: Now we have the fourth roll out of models which have xDrive. It is the X5, X3, the 5 Series and the 3 Series – including the 3 Series Coupé for the first time. In total we offer 24 different models equipped with xDrive. And we have already announced to launch an additional cross over model combining the luxury and sportiness of a coupe with genes of the BMW X5.

AI: How is your EfficientDynamics concept helping to overcome the conflict of objectives of high performance, low fuel consumption & weight?

Göschel: This is a very specific topic for BMW. Our cars are famous for driving dynamics and they are also famous for low fuel consumption. We solve the target conflict between fuel consumption and performance by what we call EfficientDynamics. We work in different areas of efficient dynamics systems. As an example let us take our gasoline engines with Valvetronic or our twin turbo six-cylinder-engine with direct injection and adjustable valve timing. This technique allows us to get the torque and power output of a V8 engine combined with lower fuel consumption and significant lower weight. On the side of diesel engines we offer a comparable concept with our six-cylinder-diesel engine with variable Twin Turbo Technology.

Simultaneously we are continuing the development of gasoline engines with direct injection and lean combustion. Thus we are getting another big advantage in fuel consumption not only in tests science but also in real traffic conditions.

AI: What does your second-generation direct gasoline injection (High Precision Fuel Injection) bring to the customer/market?

Göschel: Rhe two main areas are reducing fuel consumption and emissions. We are already reaching lean combustion up to at least 160 km/h. In our opinion this is the biggest area for improvement of the combustion engine. We will go forward with this spread guided combustion using special injection nozzles. It is a piezo controlled injection system which allows to control the mixture in the combustion chamber.

AI: Diesel v. Gasoline, who will win the battle?

Göschel: That is an interesting question. In this kind of competition today you see the diesel in the lead in regard to fuel consumption and high torque output. But with the second generation of direct injection we are reducing fuel consumption of the gasoline engine, too. With modern direct injection systems combined with twin turbo technology and adjustable valve timing we will improve also torque and power dramatically. I would say in the next years we will see such engines with 100 kW and 200 Nm per liter displacement. This is a big step. So the race will go on.

AI: What do you think will be the future of diesel in the US?

Göschel: There definitely will be a future! For the moment we think about going only with SCR systems into the US market. If we bring BMW Diesel technology to the US, it has to be one emission technology for all 50 states.

AI: What prompted BMW to enter the Two-Mode project with GM & DC?

Göschel: It is a very interesting project about hybrid co-operation with DC & GM. The technology developed under this project is top of the line. It is beyond what you have seen from the Japanese manufacturers.

There are good reasons for BMW to chose this hybrid cooperation: Based on our own expertise as shown in the Concept X3 EfficientDynamics we together with DC and GM are commonly able to align our development efforts and costs. This helps us to reach the highest level of technology maturity. Thanks to this cooperation we can bring the technology fast to the customers. Last but not least we already achieve some scaling effects in common parts.

And this all will be realized whilst still the hybrid drive train in the BMW will behave as a true BMW!

AI: What is the potential of the Two-Mode transmission?

Göschel: The biggest potential is in the solution according to our project EfficientDynamics. That is having a reduced fuel consumption of up to two digit-percentage (in miles per gallon) while in the same time an increase in dynamics and agility!

AI: Which models / vehicles will get the transmission?

We are in the pre development phase – it is too early to talk about serial cars by now.

AI: What will be the impact of hybridization on the marketability of an SUV?

Göschel: In my opinion there will be a future with hybrid systems in the car industry – which system ever might be coming out from micro to full hybrid solutions. It is a question of the segment you are selling to.

In order to give our customers already hybrid qualities, we introduce Brake Energy Regeneration and Motor Start-Stop Functions in most of our model line up from 2007 on.

But from a technological point of view first of all it is necessary to improve the efficiency of the engine even further.

And there is another open area that I think the engineers should also address: it is the question of heat loss. I feel confident that it is time to engross the thoughts on that issue. We showed a first approach with our turbo steamer system. It makes sense that the industry continues getting also these new ideas on the road.

AI: How do you see the role of the supplier in the success of BMW?

Göschel: We are looking at the scores and the studies where the best supplier relations are. There are two companies ahead of everybody else. One is coming out of Japan, the other is from Germany. This is BMW. It means that we have a fair partnership. We are developing new technologies in defined programs with suppliers. The suppliers appreciate working with us because we are looking for new technologies and innovations in a cooperative way. It is a very fair partnership.

AI: The 3-series coupe is the first to use plastic body panels for its front fenders. What prompted this decision?

Göschel: It is an internal development mainly for weight reasons. So we save energy and increase performance – a good example for BMW’s EfficientDynamics strategy. We developed a special technology in fixing the parts in the painting process in house, based on our special know-how of materials. We use a thermoplastic material which does not expand as much as others.

AI: How important for your purchasing process is the material development?

Göschel: Our main objective always is to use the ideal material for each single purpose. This is what we call Intelligent Light-Weight Design: we use light-weight materials where they really make sense.

Of course we have to keep the costs in view. If we have a look at steel, you might know that we have around 25 different kinds of high-stressed steel, depending on the different applications. When we have a look at light-weight solutions, we combine body parts – for example aluminum doors with plastic parts. We always look for the best solution for each segment or each car.

Göschel on engines

BMW is more focused on engine design than most other manufacturers, Dr Burkhard Göschel, Member of the Board of Management of BMW told a media conference at the Geneva Motor Show earlier this year.

He pointed out that “Bayerische Motoren Werke” is German for “Bavarian Engine Plantsâ€.

“So the core of our brand name is at the same time a BMW brand’s core competence: the development and production of engines. Starting with the first BMW aircraft engines, BMW engineers managed to set height and distance records – a mere two years after the company was founded in 1916. Later, other vehicles caused sensations: first the BMW motorcycles – think about Ernst Henne’s 1937 speed record – and from the 1930s on cars as well,†he said.

A modern day’s BMW engine has to meet three characteristics – namely

• sporting flair

• low weight and

• high efficiency.

Examples of how this mix is achieved include the in-line six-cylinder engine occupies a special position. After all, close to 600,000 vehicles or more than 53 per cent of all BMW vehicles sold in 2005 were driven by an in-line six-cylinder engine. “Mounting our six-cylinder engines in-line clearly distinguishes us from competitors. And we have good reason for our special approach: Among six-cylinder engines, the in-line engine is clearly the one that runs most smoothly and that vibrates the least. It also has the highest potential for reducing fuel consumption and for charging processes. This can only be done thanks to the “hot and cold side” of this engine principle, which only exists in in-line engines – and at BMW, that is our six-cylinder.

“This clever and sophisticated powertrain concept has proved its worth since 1923 – so for over 70 years – when it was first mounted in a BMW vehicle. And there is still more potential to be tapped. A prime example for efficiency and dynamics among our engines is the 3-litre 265 horsepower six-cylinder in-line naturally aspirated engine. Its advanced performance characteristics and reduced fuel consumption result from an enhanced combustion process and the Valvetronic charge cycle. Moreover, this engine is the most light-weight in its class,†he said.

Turning to diesel power, Göschel said “if the BMW Group is to enter the American market with a diesel product, it will be with one that offers a truly sustainable solution such as the exhaust treatment by SCR (selective catalytic reduction) technology – which is the drastic reduction of NOx content by use of urea. Those SCR catalytic converters dramatically lower NOx content and – in cooperation with the particle filter – reduce exhaust emissions to a minimum. However, we still have quite some way to go before this trend-setting technology will be fully developed.

“This is something BMW’s traditional diesel-powered in-line six-cylinder engines have already demonstrated: Since the launch of the very first one in the 1980s, our diesel engines have again and again been ahead of competition in terms of performance and sporting flair. The extraordinary potential that particularly the diesel in-line six-cylinder engine offers was demonstrated two years ago when we introduced the Variable Twin Turbo technology. Such a high power density would not have been feasible with any other engine type. Right now, we are still the only manufacturer applying this technology, and we are soon going to implement it into other model series.

“Future diesel engines of the BMW brand will also be based on the in-line six-cylinder engine. It allows the application of our groundbreaking Variable Twin Turbo technology in combination with concepts to reduce emissions in a most compact way, he said.â€

Saving weight

In addition to engine technology, BMW is making widespread use of weight-saving materials:

Engines. All but one current BMW engine has weight-saving basic construction materials: aluminum cylinder block and heads for V-8, V-12 and some 6-cylinder engines; as well as magnesium/aluminum composite construction in the newest 6-cylinders. Innovations include hollow camshafts and magnesium or aluminum ancillary components. Thermoplastic induction systems also reduce engine weight in some models.

Body: The front-end of all 5 and 6 Series models; aluminum hood and front fenders on the 7 Series. This has the spin-off of better front-to-rear weight distribution to improve vehicle handling.

Suspension: Lighter aluminum moving parts in the suspension system handle bumpy road surfaces better, improving handling and riding comfort.

Roof: Used for the first time on the new M6 Coupe, carbon fiber reduces overall weight and lowers centre of gravity.

Looking ahead, BMW is evaluating the BMW Active Hybrid Drive concept for high-performance vehicles on the basis of an Active Transmission and Super Cap technology. The Active Transmission supplements the conventional transmission by adding an electric power unit with integrated power electronics. This electric unit, which functions as a generator, motor and starter, replaces the torque converter.

Engine ancillaries, such as the power-steering pump, brake booster and air-conditioning compressor, are driven electrically from a high-capacity onboard electrical system. The power is stored in the vehicle in so-called Super Capacitors. The electric power functions much as a turbo- or supercharger, adding to the combustion engine’s output.

More Stories

Cybord warns of dangers of the stability illusion

How Modern Power Management Enhances Connected Fleet Tech

Automotive Industries interviews Bahar Sadeghi, Technical Director, Car Connectivity Consortium (CCC)