This has seen companies like SAP transform themselves. From being one of the world’s leading enterprise resource planning (ERP) providers SAP has grown into a provider of cloud and digital solutions. More than 50% of the company’s revenue is now generated from non-ERP services.

The transformation can be traced to the introduction of HANA (High performance analytic appliance) in 2010 and the next generation business suite S/4 HANA. This cloud version of S/4 HANA has broadened the market for the company by offering “Pay per Use” options. Since then SAP has acquired a number of cloud-centric solutions like Hybris, SuccessFactors, Ariba, Concur and Fieldglass, and now has over 200 million users in the cloud.

In addition, there is SAP Digital Boardroom which simplifies and provides performance reporting of all the business areas in real time. It includes fully automated business intelligence capabilities. SAP is also investing heavily in machine learning, blockchain, distributed ledger technology and IoT. SAP will integrate blockchain into its existing global track and trace technology to act as “an additional layer complementary to core processes that creates one shared view on the data from all involved stakeholders contributing to the supply chain,”according to Torsten Zube, SAP’s blockchain lead.

SAP earlier launched a “blockchain co-innovation initiative” to explore distributed business processes that utilize peer-to-peer networks. It is also a member of Spain’s Alastria consortium, which focuses on inter-company data sharing, and the Blockchain

in Trucking Alliance (BiTA).

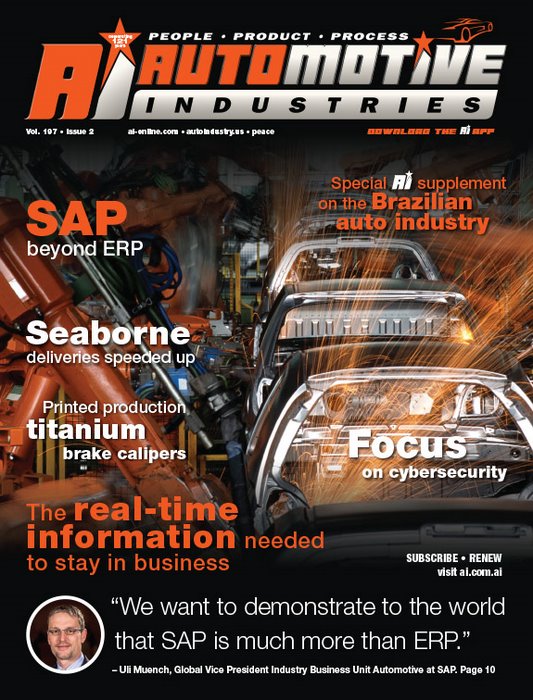

Automotive Industries (AI) asked Uli Muench, Global Vice President Industry Business Unit Automotive at SAP, how the company can help OEMs and their suppliers to transform into digital manufacturers.

Muench:We see different levels of sophistication among the OEMs and their suppliers. But, even with the more sophisticated customers there is always room for improvement. What we offer with our longstanding expertise in manufacturing is firstly our digital core solution SAP S/4 HANA, as well as our understanding of the interface between data and manufacturing. We have proven expertise in the combination of manufacturing execution and manufacturing intelligence solutions. Manufacturers who have taken advantage of this expertise include Harley-Davidson. Others, in regions like China and Japan, where there is significant investment in greenfields capacity, make use of our latest solutions designed to reduce time to market.

AI: What are the keys to success in digital transformation?

Muench: I think it has a lot to do with commitment. I don’t believe that technology is the limiting factor. It is whether or not the organization is set-up for success through transformation. It has a lot to do with the top management commitment to providing the structures and the tools to be flexible, to make sometimes tough decisions, and to be quick and ahead of the market. You don’t want to fall behind these days.

AI: What is your approach to value creation through digitalization?

Muench: What we see is that you can do a lot with technology. But, as we experience with the latest smartphones, it is increasingly hard to come up with new features to wow the market. I think what we see in the automotive industry with autonomous driving and electro mobility is a sudden quantum leap. That is a game changer.

But when it comes to technology we always have to ask ourselves and our customers what is the return on investment?

There is only one exception when the return on investment is not really critical decision factor, and that is when you have to do it to stay in business. If you are a mass manufacturer of vehicles you have to commit now to electromobility. You cannot ignore it. You have to be able to connect your assets. If you are not connected in your workplace or personally you will not be able to take advantage of optimisation levels we see with connected assets.

AI: What solutions do you offer for fleet management?

Muench: We’ve long provided fleet management solutions in the age of connected devices and connected vehicles. We’ve taken our vehicle insight solution to another level. That means that we can provide instantaneous access to in-vehicle data, for both commercial vehicles and passenger cars. This includes all the is using SAP for everything in its fully integrated enterprise solution. SAP allows them to scale and grow because they are working off a very solid platform. We have other customers coming from the tradition of internal combustion engines who are also expanding.

What we can provide with our solutions is the necessary flexibility. We are adaptable, but we do not aim to provide software for

controlling autonomous vehicles.

AI: How does the implementation and integration of SAP HANA allow companies to increase productivity?

Muench: We can use the integration of ZF Friedrichshafen and TRW Automotive as an example. For them it was a number of factors that came together perfectly. The organizational impact of integrating two organisations in a dynamic business environment is a tremendous change. It gave ZF the opportunity to see what SAP could do on a modern technology platform, and to provide the foundation for future growth.

Implementation and integration are focus areas for all our system integration partners. Take IBM for example. They are heavily investing in changing their model to be much nimbler, and to be able to implement software in much shorter cycles. At SAP we now provide a much more intuitive user interface, so there is a lot less training involved.

More Stories

SikaBaffle® technology helps customers build lighter, stronger, safer, quieter and greener vehicles

Sonatus – The industry is shifting gears to software

Cybord warns of dangers of the stability illusion