Redesign and optimization of a metal part to plastic.

Advanced simulation services at the DOMO Service Hub in Ghent, Belgium, improve reinforced polyamide component design processes for increased sustaina

bility in automotive applications

The development of electric vehicles is leading to a complete rethink in concepts. Totally new platforms are being designed to optimize electric drive technologies and associated electronics. More than ever, lightweighting across all elements of the vehicle is critical to its success. Lightweighting is a cost-effective solution obtaining maximum range and improving overall sustainable performance.

DOMO, a long-time leader in simulation services for polyamide 66 (PA66) materials, which it brands as TECHNYL A, can provide design support from the very beginning of the process of development of new components and systems. Through the DOMO Service Hub, the company supports customers throughout the development phase, including material selection, simulation, prototyping and part testing to develop more customized, sustainable and light applications.

Recently, DOMO enlarged the scope of its simulation services to cover PA6 solutions, branded TECHNYL C, as well as to more sustainable materials containing recycled polyamide (TECHNYL 4EARTH). Since February of this year, the entire TECHNYL portfolio is exclusively produced and commercialized by DOMO worldwide.

DOMO provides support in defining not only the right material, but also the right part design by simulating the material behavior and developing a functional prototype on which to perform the necessary application tests.

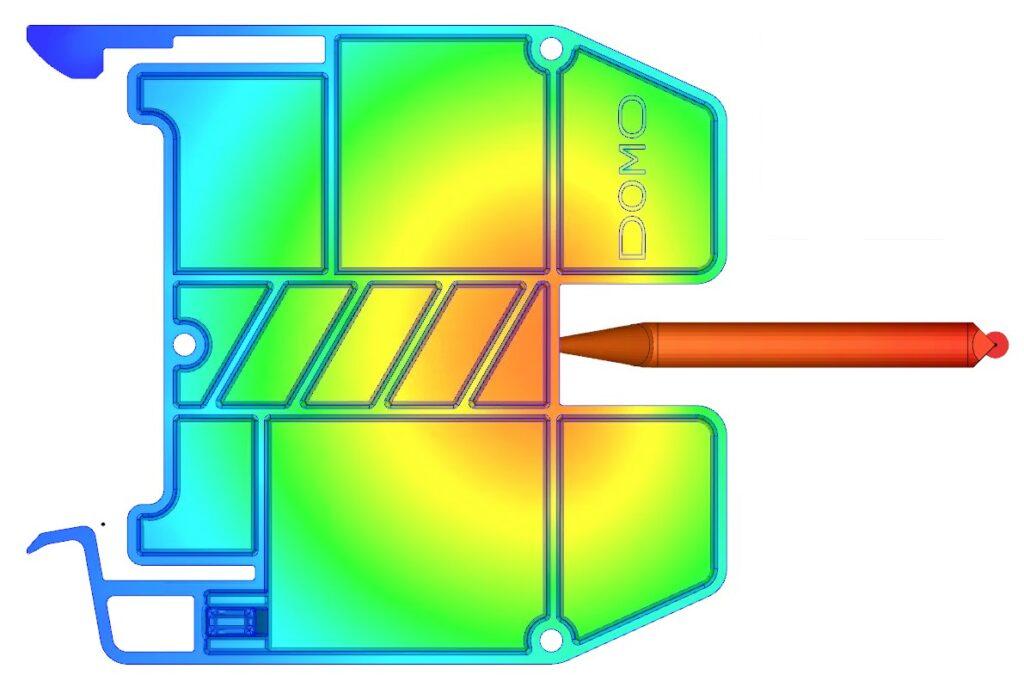

Simulations are carried out using DOMO’s MMI, a multi-scale modelling, mechanical calculation, and injection molding simulation software that supports manufacturers in understanding the real-world behavior of materials before moving forward into production. This tool grants unparalleled quality of the materials’ anisotropic data for the TECHNYL product family, making it easier to fully exploit key material properties to optimize designs and reduce time to market.

The advanced predictive simulation tool helps OEMs and parts suppliers develop stronger, lighter, more cost-effective parts injection molded in glass reinforced grades of DOMO’s TECHNYL A and TECHNYL C materials. They can confirm the technical feasibility of their applications with a high degree of predictability and limited cost compared to the expense and time of actual testing through trial and error.

This solution is allied with an extremely comprehensive materials database, and it allows for a wide range of calculations when integrated with injection process modelling. Together, they present a powerful and high-performance package that makes it possible to accurately predict the performance of injection-molded parts made from TECHNYL materials, thereby rapidly tailoring your solutions with confidence in practical performance.

The integrated technology is powered by the Digimat suite of software from Hexagon e-Xstream; material modelling technology that speeds up the development process for composite materials and structures by providing accurate and robust finite element analysis. MMI was created in a development partnership between DOMO and Hexagon e-Xstream.

For fiber reinforced materials, advanced mechanical simulations consider the orientation of glass fibers induced by the injection

molding process. DOMO teams have significant expertise in integrative simulation for the TECHNYL A range of PA66-GF materials, enabling more precise simulation results. MMI material cards lead to the most accurate and robust finite element analysis available today. Now, thanks to a concerted R&D effort on PA6-GF materials, material cards are also available for the TECHNYL C range.

MMI material cards are now available for PA6 on a wide array of glass fiber concentrations and temperatures, as well as for elastic and elastoplastic models with failure indicators. These comply with the state-of-the-art tools available in Digimat and lead to the same accurate results as those obtained for PA66 compounds. Soon, crash-dedicated and thermal models will be added to the database, as well. The new material cards are available on request in the Digimat MX application.

Materials and properties are carefully measured under a wide range of conditions, including strain rate, tensile, shear, compression, temperature and humidity. An in-house methodology for identifying polyamide matrix parameters is employed based on glass fiber measurements, covering fiber orientation and fiber length distribution. Machine learning is then harnessed to improve the efficiency of the various models, while also providing up to 15% greater accuracy compared to standard reverse engineering.

Equipment used for the specially developed tests is monitored using a video extensometer that pilots the testing devices at constant strain rates, measuring true stress and strain. A CT scan is also utilized to check the complex interior microstructure and determine the fiber alignment. Metamodels are employed to reduce the number of tests required while retaining the high level of measurement accuracy, which otherwise would represent years of testing.

The metamodel methodology enables excellent reliability since it is based on polymer physics, considering the effects of temperature, humidity and strain rate. Moreover, the database is updated regularly to maintain its high level of quality, accuracy and exhaustiveness of the physical modelling to address the most demanding applications of DOMO customers.

DOMO has built one of the largest databases in the industry, with over 42,000 files in the MMI repository, covering more than 50 grades of PA6 and PA66. Moreover, these material cards are not only limited to static load and failure, but also cover tests on a wide scope of dynamic parameters. These include impact, crash, vibration, modal frequency analysis, NVH, damping, fatigue, thermal dilation and warpage, moisture or glycol effects, and more. The files from this advanced database are made available to DOMO customers that have access to Digimat MX, and DOMO can perform simulation support in-house on their behalf.

To support the wider adoption of recycled polyamides, DOMO has also created around 700 models for various TECHNYL 4EARTH grades in Digimat. These grades are heat-stabilized grades compounded using 100% post-industrial recycled PA66, reinforced with 30, 35 or 50% glass fiber.

Once a formulation has been selected for a particular application, the next step is to optimize the design to increase the rigidity of the product. Then, an assessment is made to det

ermine the best injection molding parameters for optimal load-adapted glass fiber orientation, and any other customer criteria, to optimize the outcome.

With MMI predictive simulation, it is possible to create TECHNYL parts that are lighter, safer and less costly. Customers benefit from shorter development times, with better control over internal costs. Gilles Robert, Material Expert at DOMO explains “Material models are the end of a chain where each link has been optimized to achieve maximum accuracy. Tests are optimized to maximize precision, with material modelling relying on specifically designed procedures and meta modelling technology. This provides a higher level of accuracy than is possible with material models based on standard tests and models.”

The metamodel methodology enables excellent reliability since it is based on polymer physics, considering the effects of temperature, humidity and strain rate. Moreover, the database is updated regularly to maintain its high level of quality, accuracy and exhaustiveness of the physical modelling to address the most demanding applications of DOMO customers.

The MMI suite represents a fully industrialized process covering testing, reverse engineering, and smart model management. This tool set is particularly appreciated when it comes to the complexity of metal replacement, notably in the case of electric vehicles. Reduction of noise and vibration are of utmost importance especially in EV and polyamide-based components can support the automotive industry to improve the passenger experience.

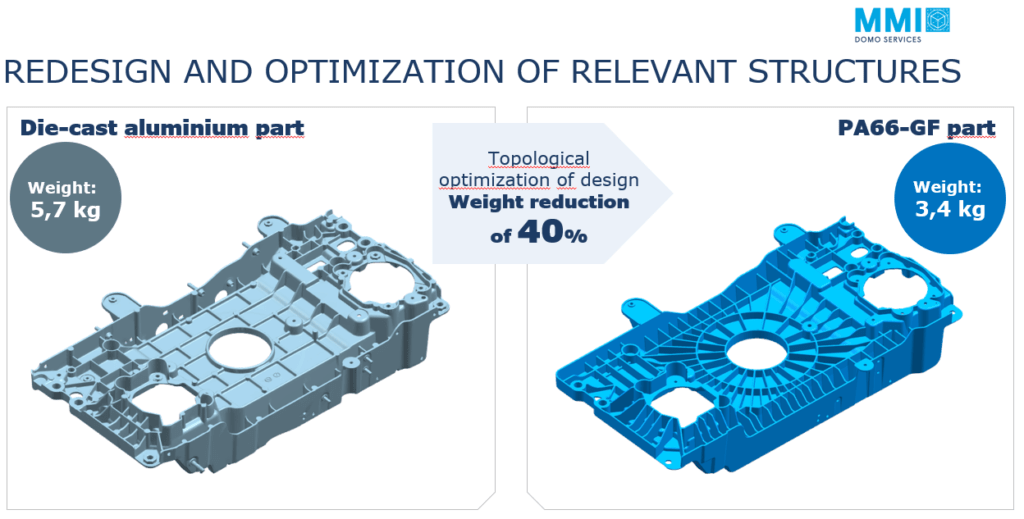

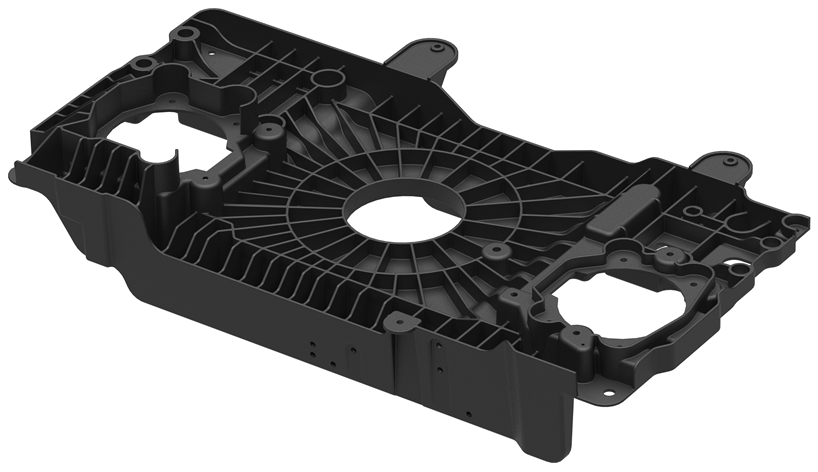

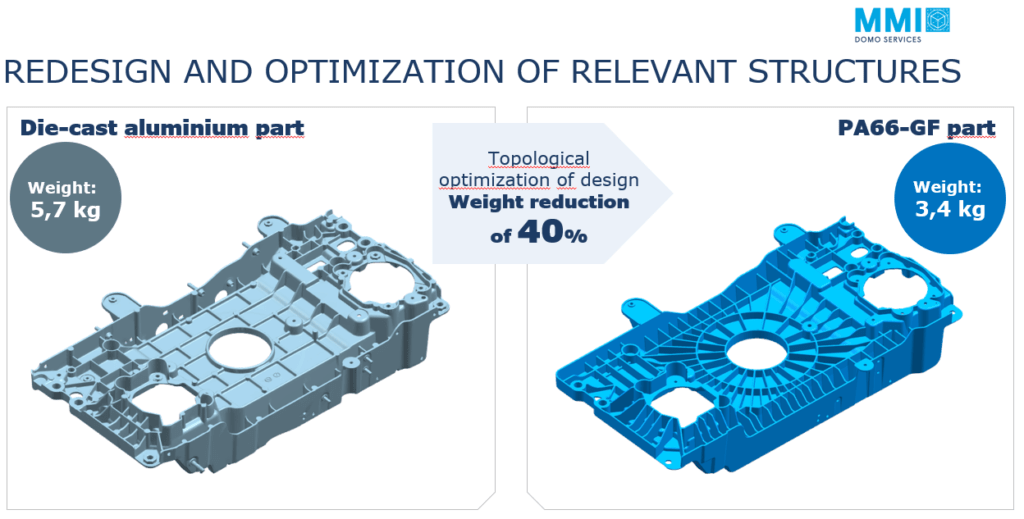

To show the power of its materials and the MMI suite, DOMO engineers took a motor mount originally made in diecast aluminum and redesigned it in a TECHNYL MAX polyamide compound containing a high level of glass reinforcement. The result was a part weighing 40% less, but with similar tensile strength values as the die cast version and up to 100 times better acoustic damping.

More Stories

Cybord warns of dangers of the stability illusion

Automotive Industries interviews Bahar Sadeghi, Technical Director, Car Connectivity Consortium (CCC)

Hexagon’s MAESTRO reinvents CMM systems through digitization