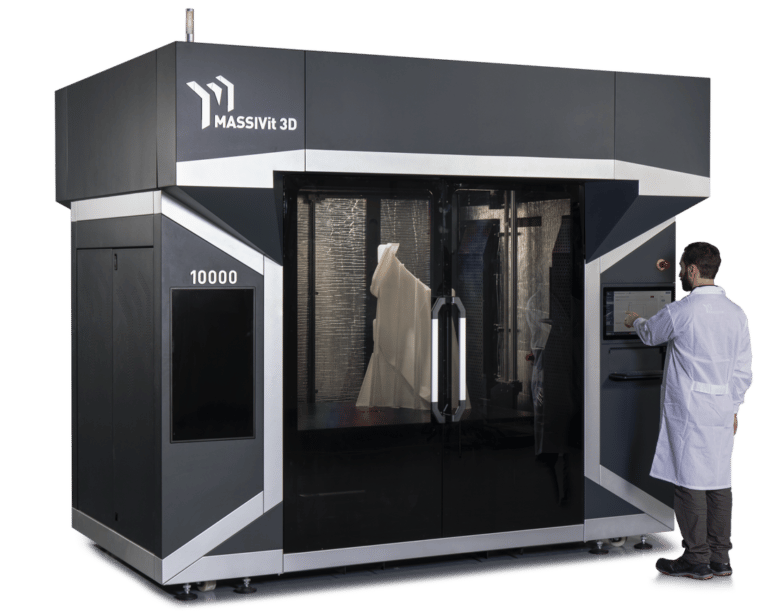

Massivit 3D Printing Technologies (Tel Aviv Stock Exchange: MSVT), the leading provider of large-scale 3D printing systems, has announced that the company will unveil the new Massivit 10000-G and its flagship Massivit 10000 to the global additive manufacturing market at the upcoming Formnext exhibition and conference in Frankfurt, Germany that takes place on November 15th-18th.

The Massivit 10000 additive manufacturing system, designed to automate and speed up mold production for composite manufacturing, was launched in May 2022 and has already drummed up significant industry acclaim, winning three awards to date. Based on the company’s Cast In Motion technology, the Massivit 10000 facilitates digital production of complex molds, mandrels, master tools, jigs and fixtures for a range of industries including automotive, rail, marine, defense, bath ware, and sporting goods. The system significantly expedites conventional mold production processes by directly casting industrial molds in a matter of days. It brings to market the first isotropic, 3D-printed mold.

The new Massivit 10000-G, the latest addition to the Cast In Motion product line, will be launched at Formnext this month. Visitors at the show will have the opportunity to see live demonstrations of the Massivit 10000-G at the Massivit 3D Booth C19 in Hall 11.1 throughout the event as well as a variety of applications and full-scale printed parts.

The Massivit 10000-G offers the full range of composite manufacturing applications available on the Massivit 10000 plus a new feature providing access to Massivit 3D’s set of Dimengel photo polymer materials that have until now been used with the company’s Gel Dispensing Printing product line.

The new feature enables customers to markedly expand their business services to include direct custom manufacturing and functional prototyping. The 10000-G also enables tooling applications for Thermoforming, Resin Transfer Molding, and Reaction Injection Molding. In addition, Dimengel materials respond to essential industry requirements such as flame retardancy, high-definition production, and a reduction in waste.

Massivit 3D will also launch a new, high-impact 3D printing material, Dimengel 400, at Formnext, showcasing industrial printed parts at the booth. Dimengel 400 is the strongest and toughest of the company’s Dimengel thermoset photo polymers to date, making it ideal for production of large, strong, and stiff end parts as well as functional prototypes, jigs and fixtures. It offers exceptional mechanical properties including double the impact resistance of existing high-performance Dimengel materials, as well as a high Heat Deflection Temperature (HDT), enabling production of large parts that can withstand elevated temperatures. Dimengel 400 will be available with both of the company’s production lines.

In addition to the Massivit 10000-G, visitors at the Massivit 3D booth will have the opportunity to see live demonstrations on the Massivit 5000 large-scale 3D printer. The Massivit 5000 leverages the company’s GDP technology that has been adopted by manufacturers for the purpose of custom manufacturing across 40 countries and a range of industries.

“We are excited to introduce our latest large-scale 3D printing technologies designed to accelerate digital transformation in the manufacturing market. In particular, the composite manufacturing arena is steeped in labor-intensive and costly processes that are long overdue for innovation” commented Massivit 3D’s CEO, Erez Zimerman. Our aim is to facilitate far more efficient processes using industrial-grade materials to maximize the true potential of composite materials.”

About Massivit 3D Printing Technologies

About Massivit 3D Printing Technologies

Massivit 3D Printing Technologies Ltd. www.massivit3D.com (Tel Aviv Stock Exchange: MSVT) is a pioneer of large-scale 3D printing solutions for the automotive, marine, railway, and furniture markets. The company’s solutions enable cost-effective production of large parts, prototypes, and molds at unprecedented speed. Massivit 3D’s vision is to advance manufacturing of large parts from traditional, manual methods to digital production by means of ultra-fast 3D printing, using industrial-grade materials. The company was founded in 2013 by a team of experts led by Gershon Miller – founder of Objet Geometry. The company’s headquarters are based in Lod, Israel.

More Stories

Venti Technologies Wins Multiple Pinnacle Awards for Innovation and Achievement in Technology

Launch of AltaScient.ai: New horizons for Risk and Sustainability Analytics

Expert Tips on Detailing a Car