Polyamide compounds are increasingly being deployed for metal replacement in the

automotive sector. To construct complex polyamide parts and assemblies, different

welding technologies are available, but engineers need to know they can count on the

joining solution. DOMO, a leading producer of TECHNYL® PA6 and PA66 compounds, has

developed a demonstrator to validate vibration welded parts performance. Working

closely with the DOMO Service HUB for design, simulation and testing, customers can

have full confidence in the part’s performance before going to production.

TECHNYL® polyamides are the lightweight alternative for many automotive applications

these days, including technical parts like engine mounts, car crossbeam and oil pan

components, and even the battery carrier for electric vehicles. DOMO, a leading producer of

polyamide 6 and 66 (PA6 and PA66) compounds, can support the development process of

these technical parts through its integrated DOMO Service HUB. This includes DOMO’s MMI

technology, combining material modelling, mechanical and injection molding simulation to

predict part performance.

Welding of injection molded polyamide parts is a common practice for producing complex

assemblies in many fields of application, including the automotive sector. DOMO can help

customers increase the efficiency of the development process through virtual prototyping

using the MMI integrative structural simulation. But proper validation of the simulation

process is also required to build confidence in the methodology, especially when it comes to

parts with important mechanical loads.

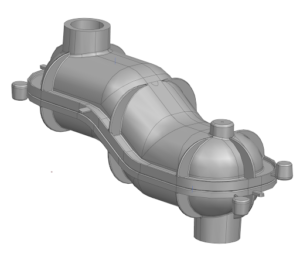

DOMO’s TECHNYL polyamide experts have therefore developed a demonstrator to test

parts performance under load and with internal pressure of fluids, to help customers

evaluate welding performance. This is backed up by the full set of DOMO testing capabilities

and expertise in highly predictive integrative structural simulations with the MMI service.

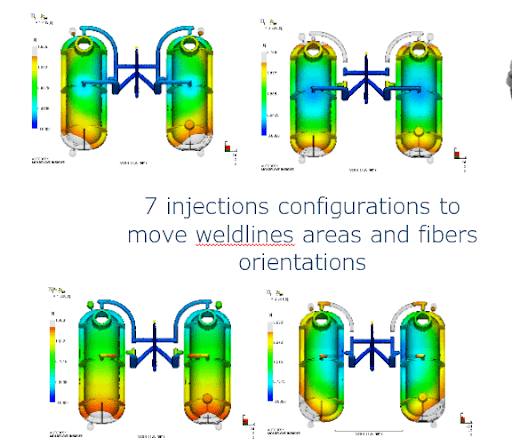

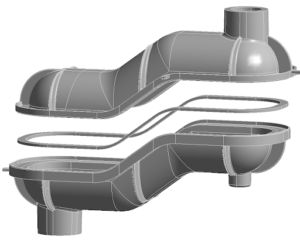

DOMO’s demonstrator for vibration welded parts enables real use-case assessment for

hollow parts like manifolds, pipes, ducts, valves, and more. This includes the ability to study

relevant injection molding effects, like melt lines of different angles and assessing the

vibration welding itself. DOMO’s demonstrator molds allow for multiple testing options for

different experimental studies, including burst pressure testing with air and long-term

coolant aging testing of welded parts. This simulation process creates a 360-degree view for

accelerated material development.

Faster time to market

As a leading producer of TECHNYL polyamide compounds with tailored properties for each

application, DOMO can provide detailed mechanical data for prediction of the part’s

performance. And with MMI, DOMO offers integrated structural simulation. Thanks to

dedicated injection and mechanical simulation files, DOMO can support customers in the

selection of the right material and the best performing design for new applications from the

very first stages of development. This includes over 34,900 analysis files for 77 grades with

multiple material behavior for PA6, PA66 and PA-HT, and glass fiber content from 15-60%.

These also cover a wide range of temperatures from, 40°C to 210°C, and a full scope of

relative humidity from 0-100%.

Thanks to MMI and the DOMO Service HUB, DOMO can achieve an excellent correlation

between simulation and actual test results, including for welded parts. This enables faster

time to market, decreased development costs and optimized parts manufacturing for

customers.

More Stories

MESSRING completes new crash test facility for Mahindra in India

ROHM Develops an Ultra-Compact MOSFET Featuring Industry-Leading* Low ON-Resistance Ideal for Fast Charging Applications

More than 30 of the top 50 global suppliers have production facilities in Turkey