DOMO Chemicals offers a new line of polyamides formulated especially

for extrusion solutions for electric vehicle (EV) cooling circuit and air

conditioning lines. The TECHNYL® SHAPE product portfolio includes

specific heat stabilized and hydrolysis resistant materials designed to

keep EV’s cool and bolster the e-mobility transition.

TECHNYL® SHAPE is a groundbreaking line of polyamide solutions for the

manufacture of hollow body plastic components and tubes, ideal for extrusion

and blow molding applications. With a compelling cost/performance ratio

compared to metal or alternative plastics, TECHNYL SHAPE provides industry-

leading polymer solutions to meet the challenges of transporting air, fluids,

glycol, fuel, refrigerants, and dielectric fluids for battery immersion cooling for

electric vehicles.

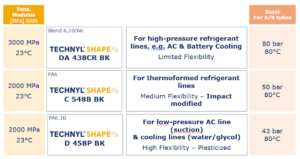

This innovative product line features easy processability as well as excellent

mechanical performance, including temperature, chemical and impact resistance,

along with specific heat stabilized and hydrolysis resistant properties. Depending

on the bursting strength requirement of the application, DOMO experts will

recommend the most suitable solutions within the TECHNYL SHAPE product

family, selecting among PA6, PA6.10/PA66 and PA6.10-based options, all with

high barrier properties to refrigerants.

Cool SHAPE

Extrusion is a process for making plastic tubes, offering a fast and effective

means for making coolant and air conditioning circuit lines. The use of

polyamides offers several advantages over metal and rubber, including low

permeability (no need for fluorination), excellent mechanical properties (lower

wall thickness possible), lighter weight, easy processing (lower cycle time) and

lower cost.

With varying pressure levels in different coolant and air conditioning lines, water

glycol lines present the least amount of pressure at 1-5 bar, while AC lines can

go up to more than 100 bar. TECHNYL SHAPE offers three different products for

extruded parts, with D458P BK, a PA6.10 solution for lower pressure that is

highly flexible; C548B BK, a medium-flexibility PA66 solution for thermoformed

refrigerant lines; and DA438CR BK, a less flexible PA6.10/PA66 solution for high

pressure AC and battery coolant lines.

Figure 1.1

TECHNYL SHAPE materials are ideal for vibration and laser welding, as well as

for overmolding in hybrid applications. Compatibility with refrigerant is also very

important and aging tests show there is no degradation of system tightness or

welding interface. In terms of permeability, these grades show excellent barrier

properties, outperforming rubber on this score, even in humid conditions.

These grades also demonstrate excellent coolant resistance at 80°C, with

elongation greater than 100% after 800 hours. At higher temperatures, they

also show good coolant resistance. For example, according to a major OEM’s

specifications for coolant circulation in pipes tested at 125°C, the pure PA6.10

product D458P BK demonstrated excellent coolant resistance.

And, during some recent test against another major OEM’s standard for

exposure to de-icing salt, both DA438CR BK and D458P BK passed the test

without cracks after at least 11 cycles.

SHAPE of things to come

TECHNYL SHAPE offers an innovative line of polyamide products for extrusion

applications for electric vehicle (EV) cooling circuit and air conditioning lines,

with varying levels of burst resistance and flexibility. They boast superior laser

weldability and excellent compatibility with R1234yf refrigerant, including with

laser welded assemblies. The TECHNYL SHAPE line also demonstrates very low

permeability to refrigerant in very harsh conditions, excellent coolant resistance,

and good salt resistance. TECHNYL SHAPE is the future of EV cooling.

Visit: https://www.domochemicals.com/en/products/technyl-engineered-materials

More Stories

Acoustic sensor systems and Fraunhofer measurement technology for in practical testing ͏

OSI Systems Receives $10 Million Order for Cargo and Vehicle Inspection Systems

Mitsubishi Electric Automotive America Launches Guardian Generation 3 Trial with Seeing Machines in North America