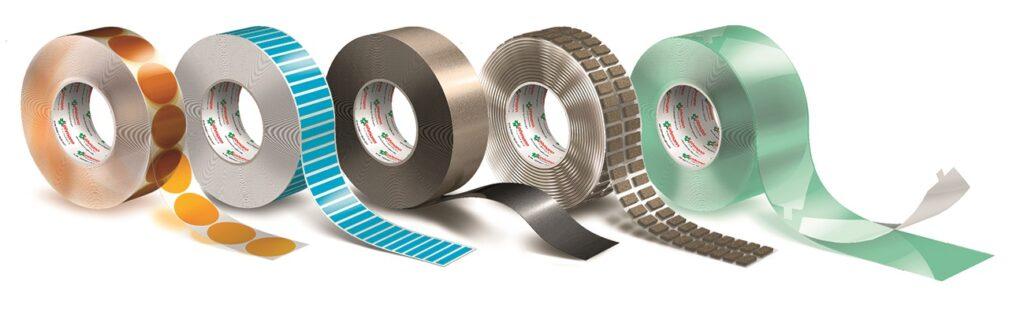

The multifunctional adhesive tape portfolio by Lohmann offers smooth thermal or electrical management and serves other functions, such as sealing, damping, electromagnetic shielding or light-blocking, vibration and shock absorption, protection or cushioning.

With the switch to electric powertrains having gained seemingly unstoppable momentum, the focus is on the batteries which store the energy for electric vehicles (EVs).

One of the technologies enhancing the performance, safety, and durability of EV batteries is functional tapes, which have emerged as a critical component. In this article, we explore the role of functional tapes in the context of EV batteries and eMobility, highlighting the advancements introduced by Lohmann Functional Tapes.

Enhancing Battery Performance

Functional tapes play a pivotal role in improving battery performance by addressing key challenges faced by EV manufacturers.

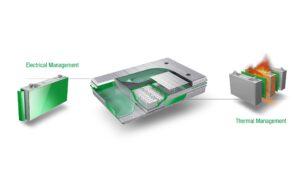

One such challenge is thermal management. EV batteries generate substantial heat during operation, which can affect performance and lifespan. By integrating thermally conductive tapes into battery modules, heat dissipation can be significantly enhanced, resulting in improved battery efficiency and prolonged lifespan.

Another critical factor in battery performance is electrical conductivity. Electrically conductive foams offer a smart solution for grounding without using springs or wires. The single-sided foam helps to enable safe grounding over lifetime by bridging gaps caused by part tolerances and thus offers reliable protection of sensitive battery components. At the same time the pressure-sensitive adhesive tape also fulfills a shielding function and helps to prevent malfunction or failure of the battery system.

Customer benefits of the DuploCOLL® EC Range.

- Isotropic and anisotropic electrically conductive

- Excellent shielding properties against electromagnetic waves according to ASTM D 4935

- Tapes available on rolls or as customized high-precision die-cuts

- Easy assembly thanks to reliable and seamless integration into highly automated production processes

Ensuring Safety and Reliability

Safety is paramount in the design and operation of EV batteries.

Functional tapes help enhance safety by providing mechanical stability and integrity to battery modules. Lohmann’s adhesive solutions offer robust bonding properties, ensuring that battery cells and other components remain securely in place even under extreme conditions, such as vibrations and impacts. This prevents potential risks associated with loose connections or structural failures, thus ensuring the safety of the vehicle and its occupants.

Additionally, functional tapes aid in the prevention of thermal runaway, a critical concern in battery technology. Lohmann’s flame-retardant tape laminations act as a barrier, reducing the risk of thermal propagation within the battery pack.

These tape laminations have been specifically engineered to meet stringent safety standards, providing an added layer of protection against thermal events.

Enhancing Battery Durability

The longevity and durability of EV batteries are key factors in their overall cost-effectiveness and sustainability. Functional tapes contribute to the durability of battery systems by providing protection against environmental factors, such as moisture, dust, and chemicals.

Lohmann’s barrier tapes create a reliable seal around battery modules, preventing the ingress of harmful substances and safeguarding the battery’s internal components.

This protection enhances the lifespan of the battery by reducing the risk of corrosion and degradation.

Furthermore, functional tapes aid in the prevention of internal short circuits within battery cells. Lohmann offers single- or double-sided PET films for high voltage insulation with high dialectric strength.

Additionally, Lohmann provides single-sided adhesive PET or PI films for the electrical insulation of the busbar

Enabling Efficient Manufacturing

Efficient manufacturing processes are crucial for the mass production of EV batteries. Functional tapes simplify the assembly of battery modules by providing reliable adhesion and ease of application. Lohmann’s tapes offer tailored adhesive properties, allowing for precise bonding of different materials commonly used in battery construction, such as metals, plastics, and composites. This flexibility streamlines the manufacturing process and reduces production time, leading to cost savings for EV manufacturers.

Additionally, functional tapes can enable the miniaturization of battery modules, facilitating the design of lightweight and compact battery packs. Lohmann’s thin and flexible tapes contribute to space-saving solutions without compromising performance or safety, thus supporting the development of next-generation EVs.

Functional tapes have emerged as indispensable components in advancing EV batteries and eMobility. Lohmann Functional Tapes provide solutions that enhance battery performance, ensure safety and reliability, extend battery durability, and enable efficient manufacturing processes.

With their innovative adhesive technologies, Lohmann contributes to the growth and sustainability of the electric vehicle industry. As the world accelerates its transition towards eMobility, functional tapes will continue to play a crucial role in shaping the future of sustainable transportation.

Customized bonding solutions

With the rapid advancements in the EV battery sector and digitalization as well as miniaturization on the rise, high-tech tape manufacturer Lohmann offers customized bonding solutions that do more than just bond.

Their multifunctional materials product range contains adhesive tape solutions that offer functions such as damping, sealing, electrical insulation or conductivity as well as reliable thermal management.

With more than half of electronic malfunctions being caused by thermal overstress, a safe and reliable heat transfer within the EV battery is key.

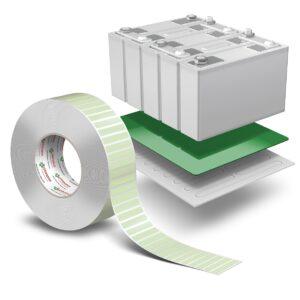

Lohmann’s new DuploCOLL TC (Thermally Conductive) range of acrylic transfer tapes provide a thermal conductivity of up to 2 W/mK, tested according to ASTM D 5470. Connected to the cooling or heating element inside the EV battery, the TC tapes help keep the temperature of the lithium-ion cells between 20 and 35 °C by enabling a homogenous heat-transfer.

Additionally, they protect reliably against corrosion and abrasive dust, thus helping to maximize the lifetime of the cells.

The range fulfills the flame-retardant requirements according to UL 94 V-0. For short-term usage the portfolio provides heat resistance up to 180 °C, while enabling a high electrical insulation with a breakdown voltage of up to 26 kV/mm.

The new TC tapes are free of silicones, halogens and solvents and provide immediate adhesion even to irregular surfaces, realizing excellent surface wetting. These thermal interface materials (TIMs) can also compensate component tolerances and seal against dust or moisture.

In contrast to liquid TIMs, the assembly is clean and easy, no additional processing tools or special storage is needed and due to the customizable format of the tapes (die-cuts), there is a high freedom of design.

They also offer several advantages to silicone gap pads besides eliminating the danger of migrating silicone oil: The tapes are tacky at room temperature and therefore no additional fixation is needed during the assembly. As screws or clamps are not necessary, the adhesive tape solutions are a weight-saving alternative, combining fixation and function in one product.

Lohmann’s thermally conductive range is available as rolls or customized high-precision die-cuts in various thicknesses from 140 μm to 2 mm. To support seamless integration into highly automated production processes, different colors are available for better detection by camera or optical sensor systems.

Lohmann’s adhesive engineers are on hand to support their partners in the industry through the entire value chain, from the formulation of the adhesive to individual product modification, high-precision die-cutting and process integration.

With a 100 % green power production at the headquarters in Neuwied, Germany, Lohmann offers the advantage of a low-CO2 European supply chain.

More Stories

Professional vs. DIY Tinting: What You Should Know

New updated edition of “PXIMate” reference guide for T&M engineers available from Pickering Interfaces

5 Mistakes That Can Ruin Your Car Accident Claim