In the fast-evolving world of electric vehicles (EVs), innovation is not just a buzzword but the driving force behind companies that are reshaping the automotive industry. At the forefront of this revolution is U POWER Tech, a visionary company led by Paul Li, the Founder and CEO. In an exclusive interview with Automotive Industries, Paul Li provides a captivating glimpse into the future of electric vehicles, sharing insights into U POWER Tech’s groundbreaking technologies, business strategies, and the global trends that are set to redefine the EV market.

The automotive landscape is undergoing a seismic shift, and at the heart of this transformation is Paul Li, the forward-thinking Founder and CEO of U POWER Tech. In a candid conversation with Automotive Industries, Li delves into the core philosophy that sets U POWER Tech apart in the competitive world of electric vehicles. Drawing parallels between traditional timepieces and cutting-edge electronics, Li emphasizes the three layers of creativity driving U POWER Tech’s success. From tailoring technologies to specific products to aligning with customer values and anticipating market demands, U POWER Tech’s approach goes beyond the conventional, setting the stage for a new era in electric mobility.

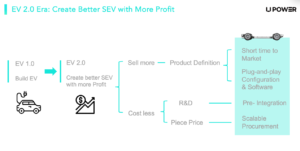

Li unfolds the intricate layers of structural innovation in EVs, advocating for a balanced approach of ‘plus, minus, times, and divides.’ From product features to diversifying profit sources and embracing a direct-to-customer model, U POWER’s strategy mirrors the dynamic shifts in the electric vehicle industry.

As the conversation unfolds, Li sheds light on the transformative impact of electric vehicles on business models. From the role of retrofit suppliers in modifying vehicles for major fleet operators to the collaborative opportunities with energy sector partners, Li paints a comprehensive picture of the evolving automotive ecosystem. The interview delves into U POWER’s role in disrupting traditional energy giants, marking a paradigm shift in the industry’s landscape.

Anticipating Trends and U POWER’s Innovations:

The spotlight turns to U POWER’s groundbreaking technology – the UP Super Board. In this section, Li articulates the architecture’s significance and its role as an integrated software and hardware operating system for smart EVs. The UP Super Board, with its “plug-and-play” chassis technology, emerges as a game-changer, drastically reducing development time for new EVs. Li details the core capabilities of the UP Super Board, from electric propulsion and suspension to steering, automated driving, and thermal management, explaining how this integration enhances overall performance and efficiency.

The conversation takes an exciting turn as Li unveils the UP VAN, the first model built on the UP Super Board platform. With industry-leading energy efficiency and a host of features designed for urban logistics and delivery scenarios, the UP VAN exemplifies the capabilities of U POWER’s groundbreaking technology.

The interview explores U POWER’s foray into electric off-road vehicles, highlighting the company’s focus on personalized driving experiences. Li discusses the challenges and opportunities in adapting electric vehicle technology for off-road applications, pointing towards a growing demand for innovative off-road features.

Technology Spotlight: HPVC and UP Hub:

Li brings attention to the core smart driving module, the High Performance Vehicle Computer (HPVC), and its flexible scalability in computing power. He explains how this flexibility benefits users in upgrading their vehicles’ computing power and adapting to different levels of autonomous driving.

The conversation concludes by examining the UP Hub’s crucial role as a domain controller with central and zonal gateway capabilities. Li elaborates on the UP Hub’s communication capabilities and how it plays a pivotal role in enhancing the overall performance and functionality of the UP Super Board.

Global Expansion and Future Trends:

The interview concludes with Li’s insights into U POWER’s global ambitions. From establishing a foothold in China and USA to expanding into the global market, Li identifies the advantageous factors within the Chinese automobile industry chain. He anticipates the rise of new electric vehicle brands, emphasizing the shift from a singular dominant player to a diverse market with unique product experiences.

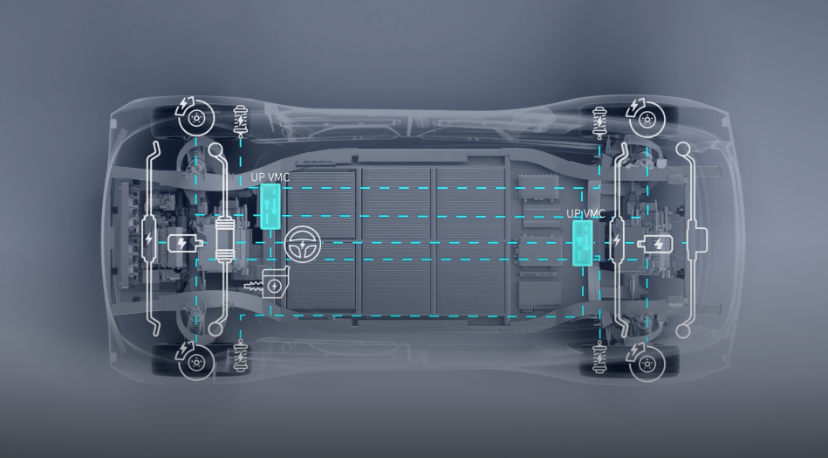

In closing, Paul Li offers a glimpse into U POWER’s architectural foundations, specifically the UP CCCA and UP VMC architecture. He elucidates how these architectures contribute to creating a robust reference architecture at both ECU and vehicle levels, reducing development cycles and allowing for seamless customization of smart EVs.

In this captivating interview, Paul Li provides not only a visionary perspective on the electric vehicle industry but also an in-depth look into U POWER’s technological innovations, business strategies, and its role in shaping the future of mobility.

Automotive Industries interview with Paul Li, founder and CEO of U POWER Tech

Automotive Industries: Hi Paul, what are your views on the future prospects of the electric vehicle industry?

Li: We believe electric vehicles (EVs) represent more than just advancements in electronics. To illustrate, consider the difference between an Apple Watch and a Rolex. While the Rolex is a mechanical-based watch known for its quality derived from an exclusive supply chain, it still exhibits timekeeping deviations, despite its premium price. In contrast, the Apple Watch, connected to the internet, offers precision timekeeping down to the millisecond. Additionally, it automatically adjusts to new time zones, showcasing its versatility. Unlike the Rolex, which focuses solely on showcasing time, the Apple Watch offers a wide array of functionalities, including monitoring blood pressure and heart rate, making it akin to an ICT terminal, much like a smartphone.

This distinction underscores our company’s philosophy, which emphasizes three layers of creativity. Firstly, innovation requires different technologies tailored to specific products. Secondly, these technologies must be applied across diverse product lines, with a keen focus on customer value. It’s crucial to understand who your customer is; for example, designing a car for a family with young children prioritizes comfort over acceleration. Li Auto’s success in designing family-centric cars tailored to specific demographics exemplifies this approach, offering a unique value proposition. Moreover, understanding these customer preferences and needs is essential for developing a sustainable business model that aligns with market demands.

I personally think what defines the structural innovation in EVs is the transformation of the entire value chain. To make EVs more popular and profitable, we must adhere to the principle of ‘plus, minus, times, and divides,’ ensuring a balanced approach. The ‘plus’ and ‘minus’ aspects entail focusing on product features and configurations, striving to make them ultimate to fit various usage scenarios. This should be our primary focus. Additionally, we must consider customer values when designing our products.

Now, what about ‘times’? It emphasizes the necessity of diversifying profit sources beyond the vehicle itself. This is why I mentioned fleet owners, taxi companies, or energy companies as potential EV manufacturers. They can leverage the vehicle as a revenue-generating asset beyond just selling it.

Another key aspect is Tesla’s direct-to-customer (DTC) approach. This shift is driven not only by a focus on manufacturing efficiency but also by the desire to retain a larger share of profits. By eliminating intermediaries like dealerships, Tesla can save significant margins, enhancing its profitability.

Moreover, we anticipate a flattening value trend from the supplier side, paving the way for a fully integrated supply chain. This integration is exemplified by innovations like skateboard chassis technology developed by U POWER Tech. Skateboard chassis serves as a pre-integrated solution, encompassing all aspects of ‘plus, minus, times, and divides.”

Automotive Industries: What changes in business models do you think electric vehicles have brought about?

Li: When considering the impact of electric vehicles on business models, it’s essential to identify the specific groups within our target audience. For instance, original equipment manufacturers (OEMs) are key players who need to understand the disruptive changes looming in related industries. At events like CES in the States, positive feedback from retrofit suppliers like Morgan highlights their role in modifying vehicles for major fleet operators such as FedEx and UPS. Morgan’s business model, centered on purchasing vehicles and chassis from companies like Ford and General Motors and customizing them to meet specific demands, underscores the potential for cost reduction in the electric vehicle market. Additionally, the promise of a positive cash flow for total cost of ownership (TCO) further emphasizes the importance of retrofit suppliers like Morgan in our target audience.

Meanwhile, our recent partnerships with customers in the energy sector signify a shift towards collaboration driven by the solutions electric vehicles offer. These energy sector partners, managing national grids and solar panels to generate electricity, face challenges in optimizing electric usage throughout the day. Our solution not only addresses these challenges but also empowers them to transform their business model. By enabling them to own assets like batteries and charge them based on electricity transactions, we mirror the stable long-term revenue streams seen in the telecom industry. This transformation highlights the broader impact of electric vehicles, disrupting energy giants like ExxonMobil and Shell, rather than Toyota and Ford.

Automotive Industries: Can you share more details about the UP Super Board and how it serves as an integrated software and hardware operating system for smart EVs? What are the key features that set it apart in the industry?

Li: I would like to begin by explaining our understanding of the Operating System. In a narrow sense, it refers to the core of the software. In a broader sense, the OS is the connecting part between the lower and upper application layers, where the skateboard chassis serves as the intermediate layer decoupling the upper and lower vehicle bodies. Based on this standardized industry common platform, our customers can focus on the upper vehicle body, which is related to personalized user experiences. This includes the development of functions such as digital cockpit, smart driving, configuration, space, and design.

The UP Super Board certainly boasts leading technical features such as full-wire control, High Performance Vehicle Computer (HPVC), Vehicle Motion Control (VMC), etc. However, comparatively, we would like everyone to understand our innovations at the levels of technology, product, and business.

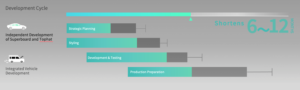

Automotive Industries: The UP Super Board has significantly reduced the development time for new EVs. Could you elaborate on how this “plug-and-play” chassis technology achieves this and the specific challenges it addresses for automakers?

Li: Enabling our customers to launch highly competitive electric vehicles in a shorter go-to-market time is one of the core values of U POWER.

In the view of U POWER, a vehicle is composed of a standardized lower body and a personalized upper body. In other words, through skateboard chassis technology, we have transformed the development of cars from “integral” to “decoupled” in parallel. The specific ways to shorten the time include:

- Removing constraints between styling and engineering development.

- The integration of the upper and lower parts of the car only requires durability verification of the upper body, while the whole-vehicle testing is not limited by seasons.

- With the production of new models based on the UP Super Board chassis, the time for tooling adjustments and process validation can be significantly reduced.

- It integrates the world’s most comprehensive and most competitive EV supply chain resources, particularly helping automakers outside of China save a lot of time spent in searching for suppliers.

Automotive Industries: The UP Super Board integrates core capabilities such as electric propulsion, suspension, steering, automated driving, and thermal management. How does this integration enhance the overall performance and efficiency of electric vehicles?

Li: As mentioned in my response to the previous question, a core value of the UP Super Board is enabling our customers to launch highly competitive electric vehicles in a shorter go-to-market time. While we can certainly help our customers in creating electric vehicles with more space and better performance, I’d like to emphasize that these are not the core factors for electric vehicles to seize a market share from a traditional internal combustion engine (ICE) vehicles segment.

Regarding how the UP Super Board enhances efficiency and performance of electric vehicles, please refer to the following details:

- The UP Super Board provides car manufacturers with a top-notch smart electric vehicle “foundation”, which is a pre-integrated core platform of an electric vehicle. Its capabilities include a range of over 1000 kilometers (621.37 miles) on a single charge, a computing power of over 1000 TOPS which meets requirements of Level 4 and above advanced driver assistance system (ADAS). With the capabilities, car manufacturers can focus more on styling, space, user experience optimization and internal operations.

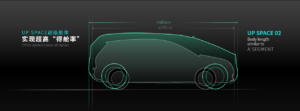

- The skateboard chassis offers significant advantages in creative design and space optimization. For example, U POWER developed concept models called the UP SPACE based on the UP Super Board, features an optimal cabin space utilization and a large flat floor, providing a remarkable advantage in both styling and spaciousness. The UP SPACE 02, a MPV concept model showcases the ultimate advantage of space: the exterior length of an A-class car with the seating experience of a B-class MPV — even more spacious legroom. It also presents the rare combination of a sporty and premium feel in an MPV model.

Automotive Industries: The UP VAN is the first model built on the UP Super Board platform. Can you highlight some unique features of the UP VAN and how it showcases the capabilities of the UP Super Board?

Li: UP VAN is the first fully complete vehicle built on the UP Super Board, specifically designed for urban logistics and delivery scenarios. Its most significant feature is achieving industry-leading energy efficiency given the volume/capacity, with UP VAN realizing a 15% increase in CLTC (Combined Load Test Cycle) range and the lowest comprehensive energy consumption unmatched in the industry. With a CLTC consumption of 14.3 kWh per 100 kilometers, this is equivalent to 4.3 miles per kWh.

Additionally, it boasts the following features:

- SUPER CONVENIENCE

- Low ground clearance – 500mm, interior cargo height of high-roof version – 1760mm, middle door – 830mm clearance, rear door effective passage – 1350mm, ensures comfortable personnel loading operations;

- SUPER BEV ARCHITECTURE

- U POWER adopts the forward development of electric skateboard chassis for commercial vehicles. The chassis platform spans across various volume levels, including 7m³ and 9.45m³.

- SUPER SMART CABIN

- UP VAN offers an array of digital cockpit features, including smartphone Bluetooth key connectivity, a 12.3-inch central touchscreen display.

Automotive Industries: U POWER’s partnership with fblife.com to create a series of electric off-road vehicles sounds exciting. How do you see electric off-road vehicles contributing to the broader electric vehicle market, and what challenges did you encounter in adapting the technology for off-road applications?

Li: Off-road scenarios represent highly personalized driving experiences, and U POWER is a new electric vehicle company that specializes in building vehicles for specific scenarios. We aim to empower our customers in creating personalized products using a standardized skateboard chassis.

We’ve observed that off-road vehicle owners not only have high demands for the basic power and off-road capability of their vehicles but expect the vehicles to provide more off-road-related features. For example:

- The skateboard chassis can integrate hub motors, providing off-road vehicles with more power and agile maneuverability, such as achieving turning on the spot and lateral movement, which is beneficial for getting out of tight spots.

- The skateboard chassis significantly frees up space in the upper body, allowing off-road vehicles to contain features such as grills, refrigerators, televisions, enhancing the camping experience.

In China, many car manufacturers have recognized the consumer demands for this scenario. As a result, Chinese brands have introduced electric off-road vehicle brands and products. For instance, BYD launched the nearly one-million RMB Yuanwang U8. Additionally, Dongfeng Motors introduced the MHERO, and Geely Motors introduced the Radar brand.

The challenge still lies in charging infrastructure. For long-distance cross-country off-roading, such as entering uninhabited areas, electric vehicles currently do not have an advantage in this scenario. However, in other off-road scenarios, electric vehicles generally have an advantage over traditional fuel vehicles.

Automotive Industries: The High Performance Vehicle Computer (HPVC), as the core smart driving module of the UP Super Board, offers flexible scalability in computing power. How does this flexibility benefit users in terms of upgrading their vehicles’ computing power and adapting to different levels of autonomous driving?

Li: U POWER HPVC undertakes the two functions of chassis domain control and intelligent driving domain control. It is the industry’s first open automotive supercomputing platform with flexible computing power. At present, U POWER has reached partnership with leading chip companies NVIDIA, Renesas and Horizon Robotics. Through different brands and different number of chips combinations, HPVC has launched different product units with different computing power levels. Then through the increase or decrease of product units, more abundant computing power configuration is realized.

Automotive Industries: The UP Hub functions as a domain controller with central and zonal gateway capabilities. Can you elaborate on how the UP Hub’s communication capabilities play a crucial role in the overall performance and functionality of the UP Super Board?

Li: UP Hub is equipped with a wealth of communication interface resources, covering all mainstream interfaces in current vehicles and supporting the vehicle-grade PCIe high-bandwidth bus standard. Functioning as a regional data transmission and processing hub, akin to highway on-ramps, it seamlessly integrates with the high-bandwidth PCIe ring communication network, ensuring high-speed data transmission.

Further details on vehicle-grade PCIe technology: With a bandwidth of up to 32Gb to 64Gb per second, it is 3 to 6 times that of the current Ethernet, capable of simultaneously transmitting data generated by approximately eight 8-megapixel cameras. Presently, an 8-megapixel front-view camera has become standard in Advanced Driver Assistance Systems (ADAS), equivalent to 0.7 visual acuity of the human eye. The next trend will involve upgrading to 12-megapixel cameras, achieving a visual acuity of 1.1, meaning the transmitted data volume will be even larger. Therefore, vehicle-grade high bandwidth has become a crucial requirement for every smart electric vehicle.

Automotive Industries: U POWER aims to establish a foothold in China and expand into the global market. What factors in the Chinese automobile industry chain make it advantageous for U POWER, and what global market trends do you anticipate will drive the adoption of U POWER’s technology?

Li: U POWER Tech was simultaneously established in Silicon Valley, USA, and Shanghai, China in 2021, inherently positioned as a global company.

Currently, the global automobile supply chain has a great presence in China, with major global automotive suppliers such as Autoliv, Bosch, Continental and Delphi running research and development centers in China. That proves the global automobile supply chain is “in China but not from China.”

The booming new energy vehicle (NEV) market has cultivated the world’s richest and most competitive electric vehicle industry in China.

- In 2023, the Battery Electric Vehicle (BEV) penetration rate in China reached 23.7%.

- In the Chinese market alone, there were 67 electric vehicle models launched in 2023.

- Companies in these supply chains have short development cycles and flexible supply.

Trend: The era of Tesla dominating the global electric vehicle market will pass, and more electric vehicle brands will emerge.

- There is a saying in China, “A single flower does not make spring, while one hundred flowers in full blossom bring spring to the garden.”

- Many new energy brands have emerged in the Chinese market, such as NIO, Li Auto, Xpeng, etc. We also announced a collaboration with Olympian Motors based in New York at CES 2024. They will use our skateboard chassis to create retro-style personalized models. These automobile brands differ from Tesla’s emphasis on efficiency, i.e., producing electric cars at the cheapest price with the highest manufacturing efficiency. Instead, they aim to provide a unique product experience. This reminds me of the year of 1903 when the largest car company in the world was Ford in Detroit, USA. The Ford Model T had a global market share of up to 80% in 1914. The founder Henry Ford once said, “Any customer can have a car painted any color that he wants, so long as it is black,” expressing his intention to meet all customer requirements with the highest efficiency and most standardized products. In the end, it was not another more efficient company that competed with Ford but General Motors, emphasizing product and brand differentiation. GM’s diversified brand and product strategy offered the market and consumers more freedom to choose, ultimately leading to a more competitive automobile industry.

Automotive Industries: The UP Super Board is based on the UP CCCA and UP VMC architecture. How do these architectures contribute to creating a robust reference architecture at both ECU and vehicle levels, and what benefits do they bring to the overall development and customization of smart EVs?

Li: The UP Super Board is highly integrated and will continue to increase its level of integration. Integration itself is a significant advantage. For example, many automotive chips currently have excess computing power because they are designed to serve a specific automotive platform, which may remain unchanged for several years or even more than a decade. However, with Moore’s Law, the computing power of chips increases rapidly, and what appears to be surplus today may be insufficient in just 12 months. The UP Super Board, with standardized interfaces, has excellent integration capabilities for upgraded chips, eliminating the need for a lot of redevelopment work.

Built on the foundation of full-wire control and enhanced by U POWER’s self-developed UP Vehicle Motion Control (VMC), the UP Super Board truly becomes a software and hardware integrated motion control system, achieving integrated control of chassis motion, unified configuration, development, and computation. This significantly improves development efficiency, tuning efficiency, as well as the efficiency of future over-the-air (OTA) updates. Time saved is cost saved. Thanks to standardized chassis actuators and intelligent standard interfaces, from the user’s perspective, compatibility with different autonomous driving companies’ solutions is possible. The modularization of autonomous driving applications is also achievable, meaning users can choose different autonomous driving algorithm providers in the same vehicle.

For OEMs, this approach effectively reduces a significant amount of software and hardware adaptation work, allowing them and autonomous driving solution providers to focus on more value-added tasks in the perception and algorithm layers, reducing manpower and development cycles.

Here is the complete working path of the full-wire control UP Super Board: Leveraging the powerful data transmission capabilities of the U POWER UP Super Board, when road conditions, vehicle motion and driver intent are captured by various sensors, their information can be instantly transmitted to the UP Hub. Subsequently, through the vehicle-grade PCIe high-bandwidth network line, the information is instantly transmitted to the UP High Performance Vehicle Computer (HPVC). The intelligent driving algorithms plan the driving path, and the UP VMC controls based on coordinates, generating the necessary instructions for each actuator terminal, such as torque, longitudinal and lateral speeds, angular velocity, execution time, execution feedback, and more. Finally, this is manifested as overall vehicle displacement, initiating a new cycle.

More Stories

What You Should Know Before Filing a Car Accident Claim

Injured in a Car Accident in St. Louis? Here’s What to Do Next

Historic Sportscar Racing (HSR) and Goodyear Announce Multi-Year Partnership