Decarbonization of the mobility industry does not start and stop with electric vehicles. Legislators and customers are demanding that OEMs address the full value chain, which includes the generation of power through solar, wind or hydro for manufacturing, logistics and the charging of EV batteries.

At the core of all the processes is the need to store energy, which is where the technology behind stationary and mobile batteries plays a crucial role.

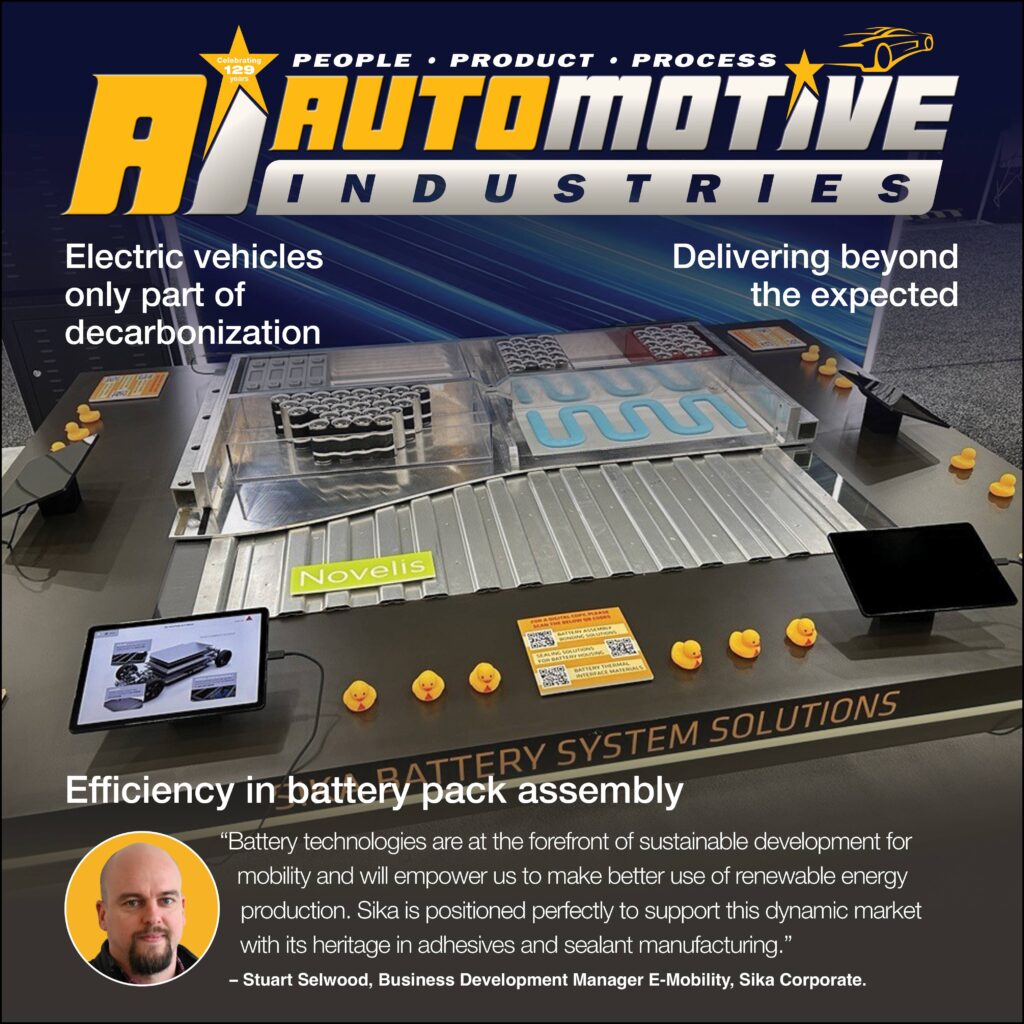

Automotive Industries (AI) asked Stuart Selwood, Business Development Manager E-Mobility, Sika Corporate, to describe the Sika homologated approach to electric battery storage and renewables.

Selwood: Sustainability drives Sika innovation and permeates our whole organization. Two of Sika’s core principles are “Courage for Innovation” and “Sustainability and Integrity”. As a result, it is important we play our part in the renewable sector.

While batteries for energy storage in electric vehicles (EVs), wind and solar are different markets, the common drive is to realize a greener, more sustainable future. Supporting our manufacturing customers in wind, solar and battery with innovative materials with low environmental impact is what we do.

Not only do we provide a global team of experts in each field to move these industries forward, but our research and development teams around the world are always working on what will be needed for the future.

AI: How does this inform your approach to EV technology development?

Selwood: EV development is a key move for global automotive manufacturers. Our understanding of passenger car manufacturing along with our decades of experience in the renewable sector align perfectly to allow us to support and advance our customers with the challenges they face in this transition to battery-electric propulsion.

Battery technologies are at the forefront of sustainable development for mobility and will empower us to make better use of renewable energy production.

Sika is positioned perfectly to support this dynamic market, with its heritage in adhesives and sealant manufacturing. Leading from the front, understanding new and future market demands allows us to invest today for the solutions of tomorrow.

AI: Sika brochures proclaim, “beyond the expected”. How does the company deliver on this promise?

Selwood: We embody “Beyond the Expected” and our customers should expect nothing less from us. The entire Sika organization is structured to allow us to deliver on this promise.

While many competitors to Sika will provide materials to the battery market, we approach all our markets with a value-add philosophy. On top of our global presence where customers can expect a person in Sika to speak the local language, understand local industry and culture, we provide a cross-section of additional services to ensure our collaboration with customers results in a successful outcome.

Our technical services teams around the world, with support from our CAE engineers, provide advice on materials selection. From there our systems engineering team helps build efficient processes for using these materials along with local commercial representation to coordinate the support needed to make your project a success.

Further, backed by a very strong customer service presence and innovations in warehousing and in the movement of goods, the customer always has a touch point.

AI: What are the latest Sika developments in thermal conductive gap fillers and adhesives, as well as bonding and sealing solutions for battery systems?

Selwood: Battery design in the global market is far from consolidated and our customers are working extensively to find the most efficient way to produce battery packs. Our technologies serve as performance enablers.

There is a combination of approaches that includes modular packs and cell-to-pack structures. Alongside this we see the use of different chemistries and cell form factors in combination with different packaging concepts and cooling strategies for optimal battery performance.

For these reasons Sika remains agile in our approach to innovation by drawing on a wide range of chemistries in our toolbox.

For gap fillers, we aim for the highest thermal transfer efficiency at the lowest weight, pushing the boundaries of our chemistries.

For thermally conductive adhesives, we work with clients to provide the right strength for performance and allow for debonding at the end of life for circularity and recycling.

Low bake and room temperature curing epoxy adhesives have been developed for fast processing and high strength while minimizing their impact on the environment.

Sika has also been a leader in sealing solutions in the market for well over a century. Using this know-how, we produce materials that can be relied upon to provide the necessary protection, whether that be a bonded and sealed joint, a boosted system for speed, a cure-in-place-gasket for servicing or a fully potted solution.

AI: What advances has Sika made in battery storage technologies?

Selwood: Sika has provided the market with numerous solutions to move the industry forward. Our portfolio includes fire protective coatings and fire-resistant materials for increased safety during a thermal runaway event.

Our best-in-class and market leading sealants ensure batteries are protected from the elements allowing for longer life and higher reliability. TIM materials with high thermal transfer properties that are not only effective in service but are easy to process making battery manufacturing more efficient and battery cooling easier to achieve, even at mass scale.

AI: Where to next for Sika?

Selwood: Sika will continue to partner with global manufacturers striving towards the next challenge, offering both performance and service benefits “Beyond the Expected”. As the world continues to embrace renewable energy in sustainability initiatives, Sika contributions will be ready to enable todays and future power generation and storage needs.

Battery technology is moving fast. Sika will remain agile and is ready to respond quickly to future moves in these applications. If sodium batteries become commercialized, Sika will be ready. If solid state batteries become affordable for mass market adoption, Sika will be ready. If silicone anodes prove to be the next step in anode technology, Sika will be ready.

More Stories

Acoustic sensor systems and Fraunhofer measurement technology for in practical testing ͏

OSI Systems Receives $10 Million Order for Cargo and Vehicle Inspection Systems

Mitsubishi Electric Automotive America Launches Guardian Generation 3 Trial with Seeing Machines in North America