PURE polyamide compounds for safer e-mobility

The e-mobility race is on, which is driving demand for engineering plastics which play a

key role in electric vehicles. However, corrosion can be a problem with certain types of

plastics in vehicle electrification. This can impair electrical functions and even lead to

serious safety issues. DOMO Chemicals’ TECHNYL® PURE range of high-purity compounds

are specially formulated to prevent corrosion and ensure safety-critical functionality, to

keep the e-mobility drive safe and securely on track.

As the race for vehicle electrification gains speed, there is growing demand for high-

performance plastics in electric, hybrid and fuel cell vehicles. There is also increasing

awareness of corrosion of these plastic components as a potential problem. This can lead to

short circuits, fire or even complete functional breakdown, posing critical functionality and

even safety issues.

Corrosion can occur when metal conductors come into contact with particular types of

plastics in certain electrical and electronic devices. The issue concerns ion migration, and

the catalysts are temperature, humidity and electric tension. A combination of these

elements can result in either corrosion, passivation (deposition) or structuration (dendrites).

Because the corrosion problem specifically concerns additives to the plastics, the purity of

plastic compounds is crucial.

PURE productivity

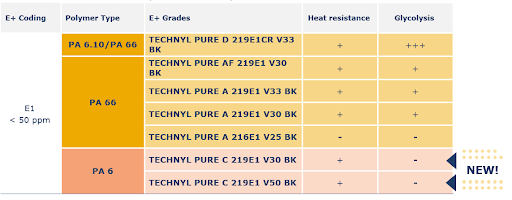

Working in close collaboration with customers in the e-mobility sector, DOMO developed a

new range of high purity polyamides to tackle this problem. The TECHNYL® PURE family

includes PA6, PA66 and PA6.10/PA66 formulations, to meet a range of application

requirements. All grades are black, non-FR, glycol and heat stable, laser markable and offer

easy processing.

TECHNYL® PURE grades are based on a clean, halogen-free formula with an organic

stabilizer and the production process follows good manufacturing practice to prevent cross-

contamination. The highest purity grade, TECHNYL® PURE J 219HT V35 BK, is fuel cell

system compliant, boasting less than 15 ppm of halide content. The ion-free formulation

eliminates metallic ions with less than 8 ppm of ion migration, according to DOMO’s

specifically defined migration test.

Target applications for the TECHNYL® PURE range include electrical and safety control

devices such as sensors, as well as electronic and transmission control units (ECU/TCU). The

higher purity grades are ideal for newly electrified functions for higher voltage cars (which

were previously mechanically driven) such as e-water pumps, e-thermostat housings and e-

valves, as well as some high voltage electrical applications such as connectors, bus bars and

charging devices (induction).

For the highest purity grade, the focus is on the fuel cell stack. This is where the hydrogen

and oxygen combine to convert into electricity. With high purity compounds, TECHNYL®

PURE can prevent critical cation and metal ion migration, which could affect the

electrochemical reaction in the fuel cell stack.

The e-mobility race is on, and electric, hybrid and fuel cell vehicles require new materials,

such as lighter, tougher plastics to replace metal. However, corrosion can be a problem with

certain types of plastics, potentially leading to functional and even serious safety issues. The

TECHNYL® PURE range of high-purity polyamide compounds are specially formulated to

prevent corrosion and make electrical components more secure. TECHNYL® PURE will help

keep the e-mobility drive safe and on track.

More Stories

What to Do After a Motorcycle Accident to Protect Yourself

Injured in a Motorcycle Crash? Talk to an Attorney Now

Danisense launches ‘Online Calibration Portal’ to offer brand agnostic calibration services for current transducers and smoothen the whole process