Researchers at Chalmers University of Technology, Sweden, have pushed

inductive power transfer technology further to enable high-power battery

charging without the need for human involvement or a robotic arm. The

technology is ready for immediate presentation to industry.

A new type of silicon carbide semiconductor and a newly developed copper

wire as thin as a human hair. These two factors have suddenly made

transmitting high power through air a realistic proposition.

Inductive charging is the new thing

Electric toothbrushes have been doing it for decades. And, in recent years,

mobile phones and other portable electronics have picked up the technology.

But until now, the wireless charging option had seemed too complex and

ineffective for the high power of electric vehicle batteries.

However, inductive charging for battery vehicles seems to have made a

breakthrough, especially when frequent charging is needed and the

environment is demanding; an urban electric ferry, for example.

Charge without human help or a robotic arm

This means that electric ferries which regularly traverse urban waterways

would not need human help or a robotic arm to charge their batteries. The

same applies to city buses or the driverless electric vehicles used in

industry, mining and agriculture.

Yujing Liu, Professor of Electric Power Engineering at the Department of

Electrical Engineering at Chalmers, is focusing closely on renewable energy

conversion and electrification of the transportation system.

“You can have a system built into the wharf that charges the ferry at some

stops while passengers get on and off. Automatic and completely independent

of weather and wind, charging can take place 30-40 times per day. This is

probably the most obvious application,” says Professor Liu.

“Even for the electric trucks of the future, there is a potential

application. The issue then is that charging these at sufficiently high

power means the charging cable is very thick, heavy and difficult to

handle”.

New possibilities due to advancements in materials

According to Liu, it is the rapid development of a handful of components and

materials in recent years that has opened up new possibilities.

“A key factor is that we now have access to high-power semiconductors based

on silicon carbide, known as ‘SiC components’. As a power source for

electronic products, these have only been on the market a few years. They

allow us to use higher voltages, higher temperatures and much higher

switching frequencies, compared to traditional silicon-based components”, he

says.

This is important because it’s the frequency of the magnetic field that

limits how much power can be transferred between two coils of a given size.

Frequencies four times higher

“Previous systems for vehicle wireless charging have used frequencies of

around 20 kHz, much like a normal stove top. They became bulky and the

energy transfer wasn’t very efficient. Now we work with frequencies that are

four times higher. Suddenly, induction becomes attractive”, explains Liu.

He adds that his research group is in close contact with the two

world-leading manufacturers of SiC modules in the world.

“With them, rapid product development is underway towards even higher

currents, voltages and power. Every two or three years, new versions are

launched which can take more. Such components are important “enablers”, with

a wide range of applications in fields like electric vehicles. So not just

for inductive charging”.

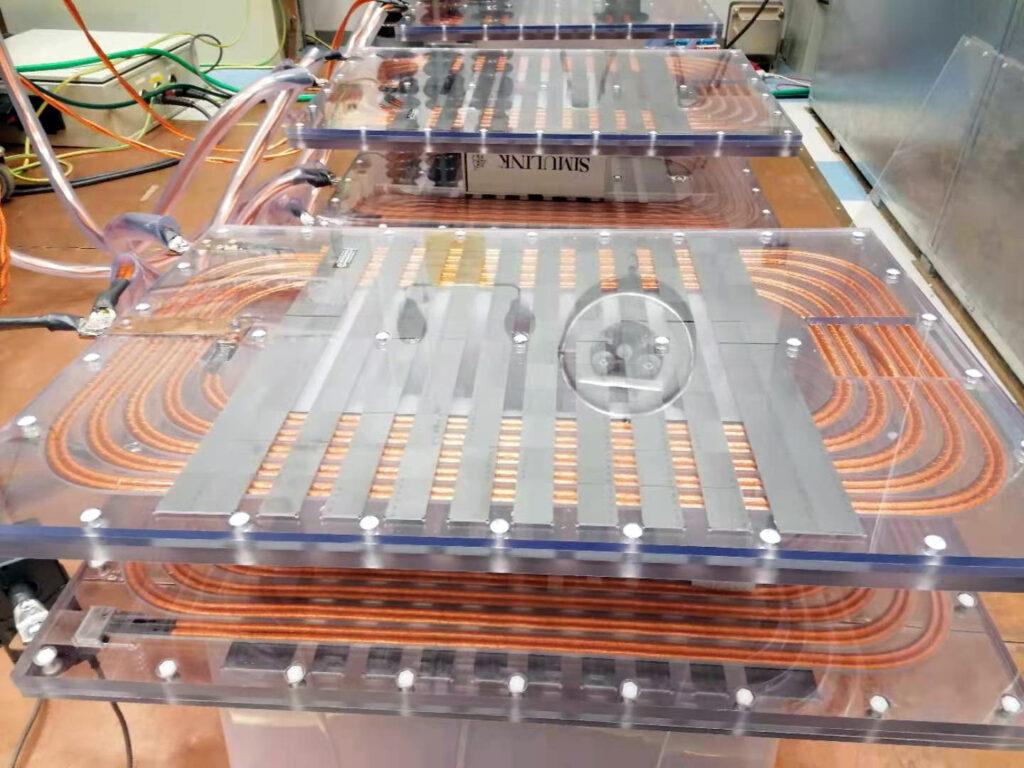

Another recent technological leap concerns the copper wires in the coils

that send and receive the oscillating magnetic field that forms the actual

bridge for the energy to flow across the air gap. The goal is to use as high

a frequency as possible.

“That won’t work with ordinary looped copper coils. It would lead to very

large losses at high frequency”, says Liu.

The new coils are made of braided “copper ropes”. These comprise up to

10,000 copper fibres, each between 70 and 100 microns thick, much like a

strand of hair.

These braids of what is known as Litz wires are optimised for high currents

and frequencies and have only been commercially available in the last few

years.

A third example that Liu highlights is a new type of capacitor used to add

reactive power. This is a prerequisite if the coil is to build up a

sufficiently powerful magnetic field. On the other hand, the magnetic field

is still very weak, even when positioned between charging plates. The stray

field decays dramatically as the distance from the charging plates

increases. Within about half a meter, it diminishes to the internationally

required level for public exposure.

Liu emphasises that charging electric vehicles entails several conversion

steps; between direct current and alternating current and between different

voltage levels.

“So, when we say that we’ve achieved an efficiency of 98 per cent from

direct current in the charging station to the battery, that figure may not

mean much if you don’t carefully define what’s measured,” explains Liu.

“But you can also put it this way: losses occur whether you use ordinary

cable-based conductive charging or charge by using induction. The efficiency

we’ve now achieved means that the losses in inductive charging can be almost

as low as with a conductive charging system. The difference is so small as

to be practically negligible. It’s about one or two per cent”.

Numbers attract attention

Liu adds that the results published by his research group have attracted a

lot of attention.

“We’re probably among the best in the world in terms of efficiency in this

power class, between 150 and 500 kW”.

Liu doesn’t think that induction charging will eventually replace charging

with a cable.

“I drive an electric car myself and can’t see that I’d have any use for

induction charging in the future. I drive home, plug in… it’s no problem”.

Is wireless charging a more sustainable technology than charging in the

usual way?

“One probably shouldn’t claim that the technology itself is more

sustainable. But it can make things easier when electrifying large vehicles

and thus speed up the phase-out of things like diesel ferries.

Facts about induction charging

* Charging by induction means that current can be transferred over a

short distance; through air, water, and other such non-metallic materials –

without any contact or conductor.

* The principle is the same as in the induction cookers found in many

kitchens. A high-frequency alternating current passed through a coil

produces an oscillating magnetic field.

* But unlike cooking, where the aim is heat development, inductive

charging means that a second coil (on board the vehicle) captures the energy

in a magnetic field and converts it into alternating current again.

Following rectification, it can then recharge the batteries.

* The heat generated in the process means that part of the energy

being transferred will be lost. Thus, minimising heating as much as possible

is an important goal in developing this technology.

Chalmers University of Technology in Gothenburg, Sweden, conducts research

and education in technology and natural sciences at a high international

level. The university has 3100 employees and 10,000 students, and offers

education in engineering, science, shipping and architecture.

With scientific excellence as a basis, Chalmers promotes knowledge and

technical solutions for a sustainable world. Through global commitment and

entrepreneurship, we foster an innovative spirit, in close collaboration

with wider society.The EU’s biggest research initiative – the Graphene

Flagship – is coordinated by Chalmers. We are also leading the development

of a Swedish quantum computer.

More Stories

Acoustic sensor systems and Fraunhofer measurement technology for in practical testing ͏

OSI Systems Receives $10 Million Order for Cargo and Vehicle Inspection Systems

Mitsubishi Electric Automotive America Launches Guardian Generation 3 Trial with Seeing Machines in North America