1353967009

Vehicle makers are coming closer to the goal of achieving a circular ecosystem with breakthroughs in the composition of thermoplastic elastomers (TPEs) and polyolefins.

TPEs with a negative, neutral, or near-zero product carbon footprint (PCF) have been developed by Avient Corporation.

The TPE formulations offer what Avient says is an industry-first cradle-to-gate PCF range between negative 0.46 and 0.0 CO2 equivalent kg/kg product while delivering comparable performance to traditional TPEs. The cradle-to-gate portion of the product life cycle refers to the carbon impact of a product from raw materials and product manufacturing.

Available in durometers of 60 and 80 Shore A, the formulations of this reSound TPE series are naturally opaque, offering an appealing aesthetic or the option to easily color if desired. The grades, which overmold to polypropylene and polyethylene, are customizable, but formulation changes could impact the product carbon footprint and will require recalculation, says the company.

Avient follows the ISO 14067:2018 standard to calculate PCF values and utilizes global formulation expertise, green manufacturing processes, and sourcing and logistics competence to achieve such low or negative values.

Avient has also introduced new recycled and bio-based polyolefin formulations. Maxxam™ REC recycled polyolefins are formulated with 25-100% recycled resin from post-industrial recycled (PIR) and post-consumer recycled (PCR) sources.

Maxxam™ BIO bio-based polyolefins are formulated with 15-100% bio-based resin and/or natural filler from renewable plant sources. Both solutions offer a more sustainable alternative to traditional polyolefin grades while achieving comparable performance.

The new formulations can be fully customized to meet specific application needs, according to Avient. They can be filled and reinforced or blended with glass, minerals, impact modifiers, colorants, and stabilizer systems to satisfy the required performance characteristics, including flame retardant performance. Maxxam™ BIO formulations are natural and are easy to color, it adds.

Avient has also announced that Nymax™ BIO bio-based polyamide formulations are now available in Europe, with formulations between 16% and 47% natural filler from renewable plant sources, including corn, straw, and wheat. Manufactured at Avient’s Shanghai plant in Asia when launched, these grades are now also manufactured locally in Avient’s facility in Germany.

The Maxxam™ REC & BIO formulations can improve the sustainability of automotive applications, including HVAC systems, engine guards, battery housings, and flame-retardant applications. And the Nymax™ BIO bio-based polyamide formulations can be used in Transportation/Automotive applications such as lid components of EV batteries, HV connectors, housing covers of EV battery packs, and engine covers.

Automotive Industries (AI) asked Hermann Fuechter, senior Marketing and Product Manager EMEA at Avient Corporation, what the company is focusing on.

Fuechter: For us at Avient, sustainability is a core value. We are working on numerous bio and recycled content projects with the objective of providing the best performing solutions for all our customers, depending on their criteria.

AI: What about lightweighting solutions to replace traditional materials such as metal and glass?

Fuechter: We’re a global company and are focusing on the whole market. We are not bound to any specific polymer platform. Our target is to find the best solution for our customers. Solutions are found from the polyolefins up to the high-temperature resins. We are creating solutions to meet the mechanical performance and lightweighting requirements of our customer. So, it is a close collaboration to understand what exactly our customers are looking for, in terms of mechanical requirements, sustainability requirements, about chemical impacts.

AI: What are the latest additions to your growing sustainability portfolio (Maxxam REC and Maxxam BIO polyolefins)?

Fuechter: They add on to our waste and sustainability strategy by broadening our portfolio in the recyclability and bio portfolios. The goal with these new technologies is to match the performance of prime material with a far better carbon footprint with a far better impact on sustainability than traditional prime materials. They can be used in the same way as the traditional materials and consist of 15 to 100% bio-based resin and/or filler from renewable plant sources or recycled polymers.

AI: Can the new formulations be fully customized to meet specific application needs?

Fuechter: Here again our business model is to provide customization in close collaboration with our customers. So, we are looking specifically at their criteria and their requirements, in order to help them to position themselves as market leaders by providing the right materials for their requirements.

AI: Are these bio-based formulations are available in Europe?

Fuechter: The bio-based polyamides are now being produced in Europe, as well as being available on other continents.

AI: You have introduced carbon negative and carbon neutral thermoplastic elastomers. How do they help customers to meet their sustainability goals?

Fuechter: These new products add to our sustainability strategy. It is new technology where we combine the sourcing with sustainable ways of production. The result is industry-first TPEs with a net zero or even negative carbon footprint.

AI: What’s next for Avient?

Fuechter: As a company we are looking for sustainability. And we are of the firm belief that there is a trend in all industries towards a circular economy. It affects not only products, but also packaging. This is what will bring the most value in the future. And so, our strategy is pursuing the eight ways that we defined in which we can support our customers through our solutions to meet their sustainability targets.

We are developing and customizing and also screening the market on the raw materials side, to enable our customers to meet their sustainability targets, and broaden our material base.

Block

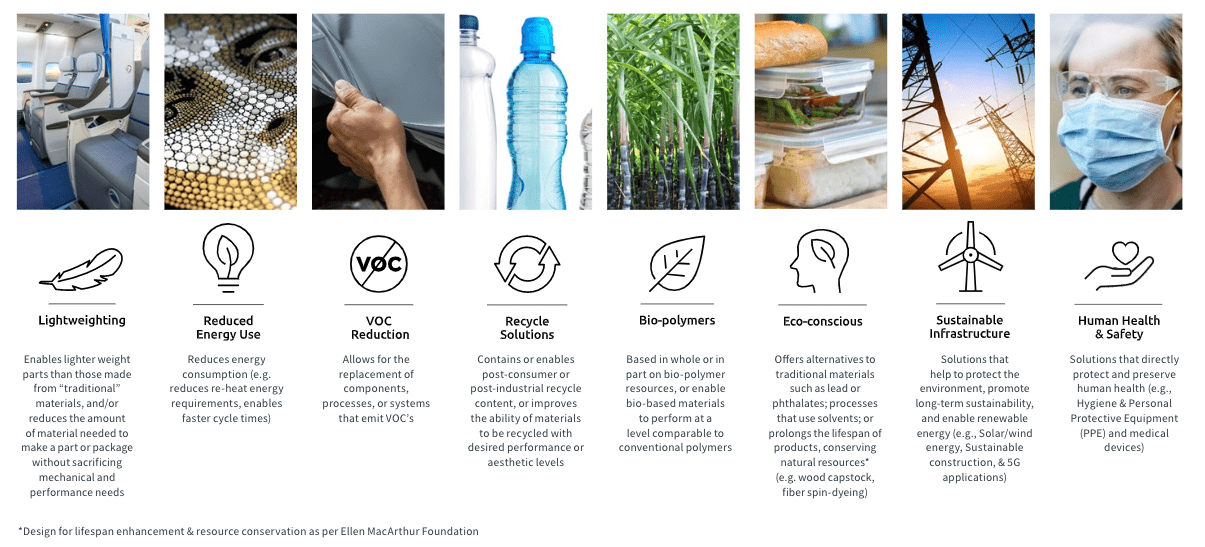

Eight ways Avient helps customers meet sustainability goals

- Lightweighting: Enables lighter weight parts than those made from “traditional” materials, and/or reduces the amount of material needed to make a part or package without sacrificing mechanical and performance needs

- Reduced energy use: Reduces energy consumption (e.g. reduces re-heat energy requirements, enables faster cycle times)

- VOC Reduction: Allows for the replacement of components, processes, or systems that emit VOCs

- Recycle solutions: Contains or enables post-consumer or post-industrial recycle content, or improves the ability of materials to be recycled with desired performance or aesthetic levels.

- Bio-polymers: Based in whole or in part on bio-polymer resources, or enable bio-based materials to perform at a level comparable to conventional polymers

- Eco-conscious: Offers alternatives to traditional materials such as lead or phthalates; processes that use solvents; or prolongs the lifespan of products, conserving natural resources (e.g. wood capstock, fiber spin-dyeing).

- Sustainable infrastructure: Solutions that help to protect the environment, promote long-term sustainability, and enable renewable energy (e.g., Solar/wind energy, Sustainable construction, & 5G applications)

- Human health & safety: Solutions that directly protect and preserve human health (e.g., Hygiene & Personal Protective Equipment (PPE) and medical devices).

More Stories

Acoustic sensor systems and Fraunhofer measurement technology for in practical testing ͏

OSI Systems Receives $10 Million Order for Cargo and Vehicle Inspection Systems

Mitsubishi Electric Automotive America Launches Guardian Generation 3 Trial with Seeing Machines in North America