Industrialization of fuel cell bipolar plates: Innoplate goes into operation

Innoplate, a 50/50 joint venture of Schaeffler and Symbio, celebrated today the inauguration of its new production site for fuel cell bipolar plates (BPP) in Haguenau, France. Bipolar plates are a strategic component for fuel cell technology and Innoplate represents a compelling industrial combination leveraging the technological and industrial strengths of its founding companies. With an initial current production capacity of 4 million bipolar plates, Innoplate is expected to reach 50 million annually by 2030, thus, strongly contributing to the ramp-up of hydrogen mobility in Europe.

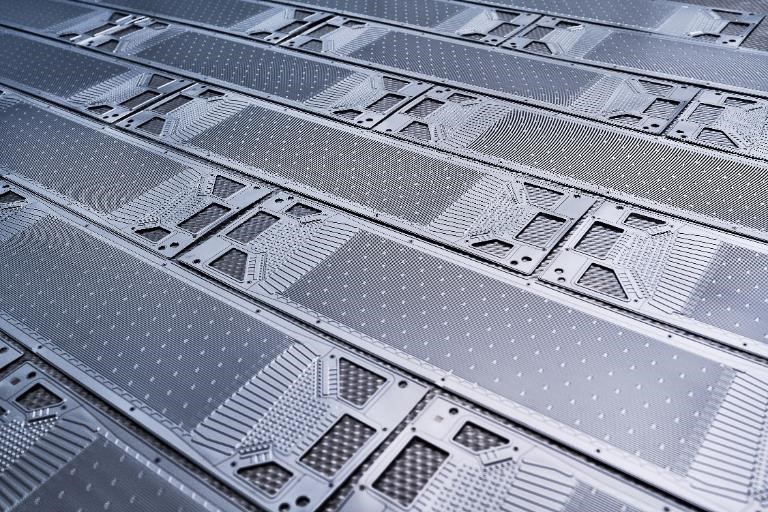

Industrializing the next generation of bipolar plates

Schaeffler and Symbio have effectively joined forces at Innoplate to mass produce next generation metallic BPP for fuel cells and support hydrogen-clean mobility emergence. Innoplate aims at accelerating the production of next generation BPP for the entire proton exchange membrane (PEM) fuel cell market, thus enhancing performance, capacity, and cost competitiveness for its customers. Schaeffler brings its industrial excellence and OEM expertise in areas such as steel pro-cessing and coating technology, and Symbio its highly integrated know-how in fuel cell design and production. Innoplate production has started in the first quarter of the year and is already equipping Symbio fuel cell systems.

Klaus Rosenfeld, CEO of Schaeffler AG, said: “At Schaeffler we are convinced that hydrogen will play a fundamental role in the sustainable mobility of tomorrow, especially in the heavy-duty area. By starting the production of next generation bipolar plates for fuel cells in our joint venture Innoplate together with Symbio, we are proud that our innovative production technologies and industrial know-how can contribute to both cleaner and climate friendly mobility, and to strengthen the Franco-German partnership.”

Philippe Rosier, CEO of Symbio, stated: “Fuel cell bipolar plates are a critical component of fuel cell systems. Innoplate serial production capability is instrumental in order to secure our strategic sourcing and enable enhanced system performance and an effective step-up in cost competitiveness. Symbio is honored to join forces with Schaeffler to reinforce the European supply chain for hydrogen fuel cells with an innovative production system and a cutting-edge technology.”

Contributing to key European industries and competencies

Located in the French city of Haguenau, close to German border, the Innoplate plant will contribute to strengthening the European hydrogen industry and supply chain, that is set to play a key role in decarbonizing the economy and mobility. With the start-of-operations of the Innoplate plant, it is the first time that bipolar plates are mass-produced on the European continent. The Innoplate plant project is supported by the France 2030 program and is intended to play a positive role in the local employer pool, creating 120 jobs by 2030. The site, which is located in close proximity to the Schaeffler plant in Haguenau, was built according to highest sustainability standards and ensures net zero-emission operations.

Successful inauguration event onsite

Innoplate inauguration was honored by 150 guests that followed the invitation of Klaus Rosenfeld, Philippe Rosier, and Innoplate Managing Directors Alain Haag and Cédric Handwerk to the event. In their joint speech, Alain Haag and Cédric Handwerk, Managing Directors of Innoplate, spoke about the challenges they have mastered together with their teams in a very short timeframe. “Only eighteen months ago Innoplate was constituted. As soon as the concrete was dry, machines, tooling and a laboratory have been installed while setting up the appropriate IT infrastructure,” said Alain Haag. “And we succeeded – from zero to four million units within such a short period, and most importantly without any accidents or delays. We are ready to ramp up production.” Cédric Handwerk added: “We want to thank our Innoplate team here onsite for their extraordinary efforts and our mother companies, Symbio and Schaeffler, for their unwavering support.”

More Stories

Unique Vacation Experiences for the Car Enthusiast

Mecum Auctions Sponsors Monterey Motorsports Festival for Car Week

How to Set Up Your Garage with the Right Equipment for Auto Repairs