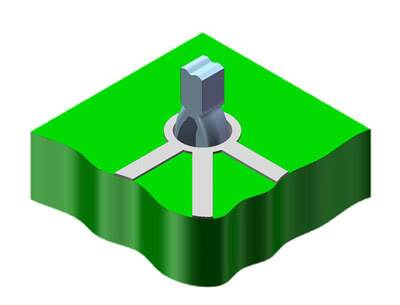

With press-fit technology, an electrical connection is created between the connector and the PCB by pressing a connector pin into a plated-through PCB hole.

The press-fit technique is based on a simple principle:

The press-fit zone of a contact pin has a larger diagonal cross-section than the metallized PCB hole. The deformation that occurs during press-fitting is reduced by the flexible zone on the contact pin.

The PCB sleeve is therefore only deformed to a very small extent. During the press-fit process, a cold weld is created between the contact pin and the metallized PCB hole: a gas-tight, corrosion-resistant, low-resistance and electrically conductive mechanical connection.

It remains contact-safe and stable even under very high mechanical and thermal loads, such as vibration, bending and strong temperature changes.

ept recommends real-time monitoring during the press-fit process: force-displacement and camera monitoring allow the connection point to be accurately determined.

In addition to the proven press-fit technology with ept’s Tcom press® press-fit zone, the company offers many other connection technology options. Whether soldered through-hole plating, THR or SMT – ept has the right solution for every application.

Press-fit technology: What you need to know

Conductor tracks press-fit technology

The press-fit technology is easy to handle if the specification is adhered to. Four parameters play a key role here:

The drill diameter and the diameter of the metallized press-fit hole, the thickness of the copper sleeve in the press-fit hole and the PCB surface.

If both SMD components and press-fit connectors are to be accommodated on a PCB, a certain sequence must be observed:

The components with solder connections must be mounted first. Once all components have been soldered onto the PCB using a suitable process, the press-fit connectors can be mounted.

This sequence is important: reversing the process sequence would result in a high thermal load on the press-fit connections. This would lead to subsequent (uncontrolled) soldering of the press-fit zone, which would no longer guarantee an intact gas-tight zone.

In addition, the correct distance to the edge of the PCB and to sensitive electronic components (e.g. ceramic components) as well as the connections of the conductor tracks must be observed.

Maintaining the minimum distance prevents the PCB material or electronic components from being damaged by the force of the press-fit zone and the PCB layers from being destroyed.

Press-fit technology: Advantages

- Most robust and reliable connection technology

- Long-lasting durability

- Gas-tight connection

- High holding forces

- No soldering defects, flux residue or similar

- No additional cleaning necessary

- Recycling possible by simply pressing out

- Efficient and cost-effective assembly process

Press-fit technology: ept’s solution for the automotive industry

ept manufactures several billion contacts per year for various sectors and applications in the automotive industry.

The company’s press-fit zones consist of strip thicknesses of 0.2 to 1.2 mm for hole diameters of 0.56 to 2.0 mm or according to client requirements.

More Stories

Automechanika Shanghai’s 2025 fringe programme spotlights sustainability and fosters collaboration

DOMO Chemicals accelerating sustainable innovation in polyamides

Navi Auto Transport using technology to move cars faster and safer